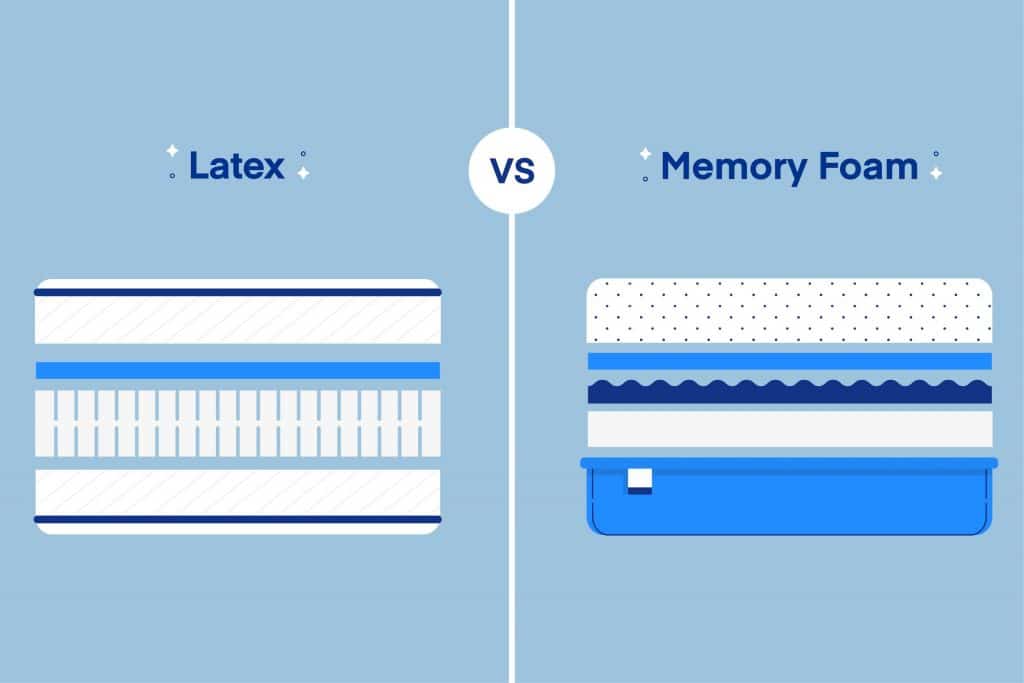

Are you in the market for a new mattress? If so, you may have come across memory foam mattresses. These types of mattresses have become increasingly popular in recent years due to their ability to provide a comfortable and supportive sleep surface. But have you ever wondered how these mattresses are made? In this article, we will delve into the top 10 manufacturing processes for memory foam mattresses.Memory Foam Mattress: A Guide to Understanding the Manufacturing Process

Before we dive into the manufacturing process, let's first understand what memory foam is. Memory foam is a type of polyurethane foam that is known for its ability to conform to the shape of a person's body. It was first developed by NASA in the 1960s to provide cushioning for astronauts during space flight. Today, it is widely used in mattresses, pillows, and other bedding products.1. What is Memory Foam?

Memory foam mattresses offer a range of benefits, including pressure relief, motion isolation, and durability. The foam's ability to conform to the body's shape helps alleviate pressure points, making it an excellent choice for those with back pain. Additionally, memory foam mattresses are known for their ability to isolate motion, making them an ideal choice for couples who don't want to be disturbed by their partner's movements. Lastly, memory foam mattresses are highly durable and can last up to 10 years with proper care.2. The Benefits of Memory Foam Mattresses

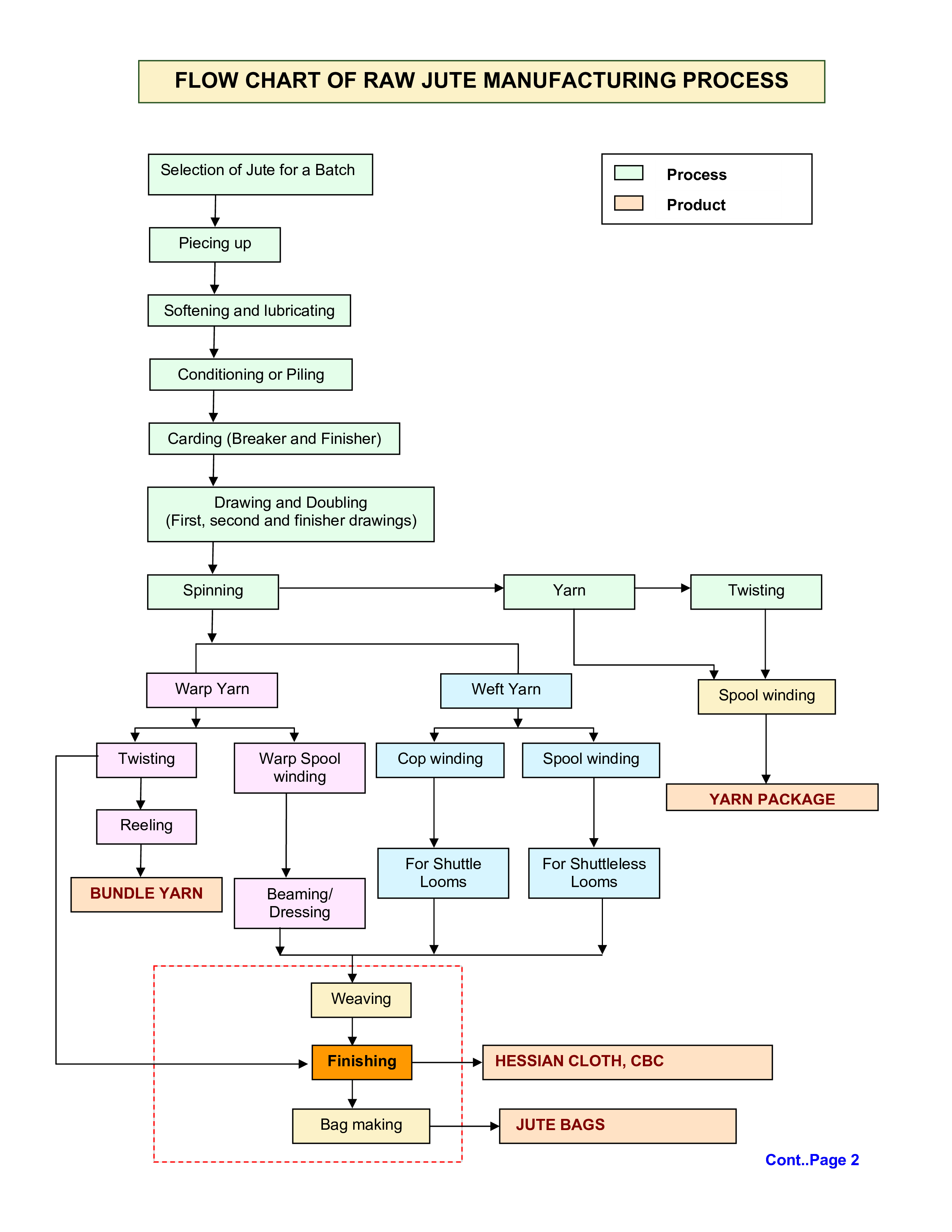

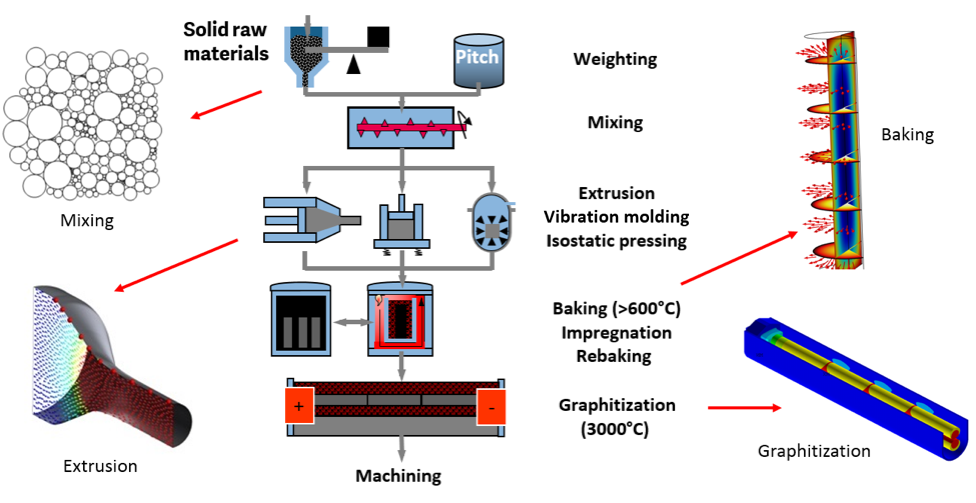

The manufacturing process for memory foam mattresses involves several steps, including mixing, pouring, and curing the foam. Let's take a closer look at each of these steps.3. The Manufacturing Process

The first step in the manufacturing process is mixing the foam. The ingredients, which include polyol and isocyanate, are mixed together in a large vat. The amount of each ingredient used will determine the density and firmness of the foam. This mixture is then left to sit for a few minutes to allow for proper expansion.4. Mixing the Foam

Once the foam has expanded, it is poured into a mold. The mold is typically in the shape of a mattress, and the foam is poured in layers to ensure even distribution. The foam is then left to cure for several hours.5. Pouring the Foam

After the foam has cured, it is removed from the mold and cooled. Once cooled, the foam is cut into the desired size and shape. This step is crucial as it ensures the foam is the correct size for the mattress and any additional layers or features.6. Cooling and Cutting

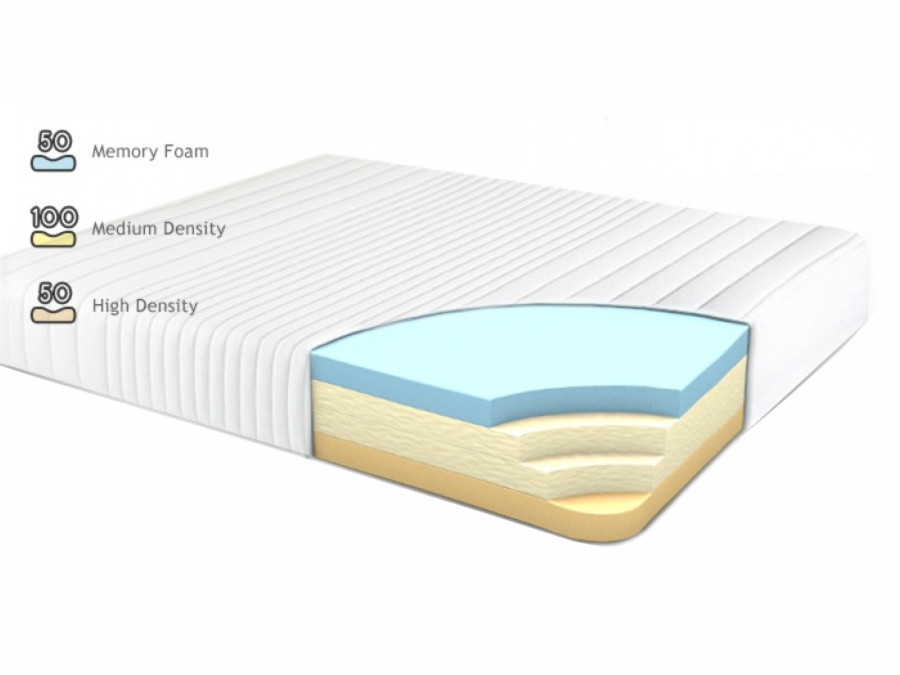

In some cases, memory foam mattresses may have additional layers, such as a base layer for support or a cooling layer to regulate temperature. These layers are added during the manufacturing process and are carefully placed on top of the memory foam layer.7. Adding Additional Layers

After the foam layers are assembled, the cover is sewn onto the mattress. The cover is typically made from a stretchy, breathable material that allows for the foam to conform to the body's shape. This also helps with temperature regulation and moisture-wicking.8. Sewing the Cover

Before the mattress is packaged and shipped, it goes through a series of quality control and testing measures. These include checking the foam's density and firmness, ensuring the cover is properly sewn, and testing the overall comfort and support of the mattress.9. Quality Control and Testing

The Benefits of Memory Foam Mattresses

Superior Comfort and Support

One of the main reasons why memory foam mattresses have gained popularity is their ability to provide superior comfort and support. Traditional mattresses often cause pressure points, leading to discomfort and disrupted sleep. However, memory foam mattresses

conform

to the body, evenly distributing weight and relieving pressure points. This results in a more comfortable and supportive sleep experience, allowing you to wake up feeling refreshed and well-rested.

One of the main reasons why memory foam mattresses have gained popularity is their ability to provide superior comfort and support. Traditional mattresses often cause pressure points, leading to discomfort and disrupted sleep. However, memory foam mattresses

conform

to the body, evenly distributing weight and relieving pressure points. This results in a more comfortable and supportive sleep experience, allowing you to wake up feeling refreshed and well-rested.

Improved Spinal Alignment

Sleeping on a memory foam mattress can also have a positive impact on your spinal alignment. The foam

contours

to the natural curves of your body, providing support to your spine and promoting proper alignment. This can be especially beneficial for those with back pain or other spinal issues.

Sleeping on a memory foam mattress can also have a positive impact on your spinal alignment. The foam

contours

to the natural curves of your body, providing support to your spine and promoting proper alignment. This can be especially beneficial for those with back pain or other spinal issues.

Reduced Motion Transfer

Another advantage of memory foam mattresses is their ability to reduce motion transfer. This means that when your partner moves or gets out of bed, you won't feel it as much on your side of the mattress. This can be a game-changer for couples who have different sleep schedules or are easily disturbed by movement.

Another advantage of memory foam mattresses is their ability to reduce motion transfer. This means that when your partner moves or gets out of bed, you won't feel it as much on your side of the mattress. This can be a game-changer for couples who have different sleep schedules or are easily disturbed by movement.

Durability and Longevity

Memory foam mattresses are also known for their durability and longevity. The manufacturing process involves creating a dense and resilient foam that can withstand years of use without losing its shape or support. This makes it a worthwhile investment for your sleep and overall health.

Memory foam mattresses are also known for their durability and longevity. The manufacturing process involves creating a dense and resilient foam that can withstand years of use without losing its shape or support. This makes it a worthwhile investment for your sleep and overall health.

Hypoallergenic and Dust Mite Resistant

For those who suffer from allergies, memory foam mattresses are an excellent choice. The dense foam

prevents

the accumulation of dust mites and other allergens, making it a hypoallergenic option for a healthier sleep environment.

In conclusion, the memory foam mattress manufacturing process results in a high-quality sleep surface that offers superior comfort, support, and a host of other benefits. Its ability to

conform

to the body, promote spinal alignment, reduce motion transfer, and resist allergens make it a top choice for those looking to improve their sleep and overall well-being. With its longevity and durability, a memory foam mattress is a wise investment for a good night's sleep for years to come.

For those who suffer from allergies, memory foam mattresses are an excellent choice. The dense foam

prevents

the accumulation of dust mites and other allergens, making it a hypoallergenic option for a healthier sleep environment.

In conclusion, the memory foam mattress manufacturing process results in a high-quality sleep surface that offers superior comfort, support, and a host of other benefits. Its ability to

conform

to the body, promote spinal alignment, reduce motion transfer, and resist allergens make it a top choice for those looking to improve their sleep and overall well-being. With its longevity and durability, a memory foam mattress is a wise investment for a good night's sleep for years to come.