Foam mattresses have become increasingly popular in recent years due to their comfort and support. However, many people may not realize that the production of foam mattresses involves the use of various chemicals. These chemicals play a crucial role in creating the foam that makes these mattresses so comfortable. In this article, we will explore the top 10 chemicals used in the making of foam mattresses.Foam Mattress Chemicals

The process of making foam mattresses involves several steps, including mixing, pouring, molding, and curing. During these steps, various chemicals are added to create the foam and give it its desired properties. Let's take a closer look at the top 10 chemicals used in foam mattress making.Foam Mattress Making

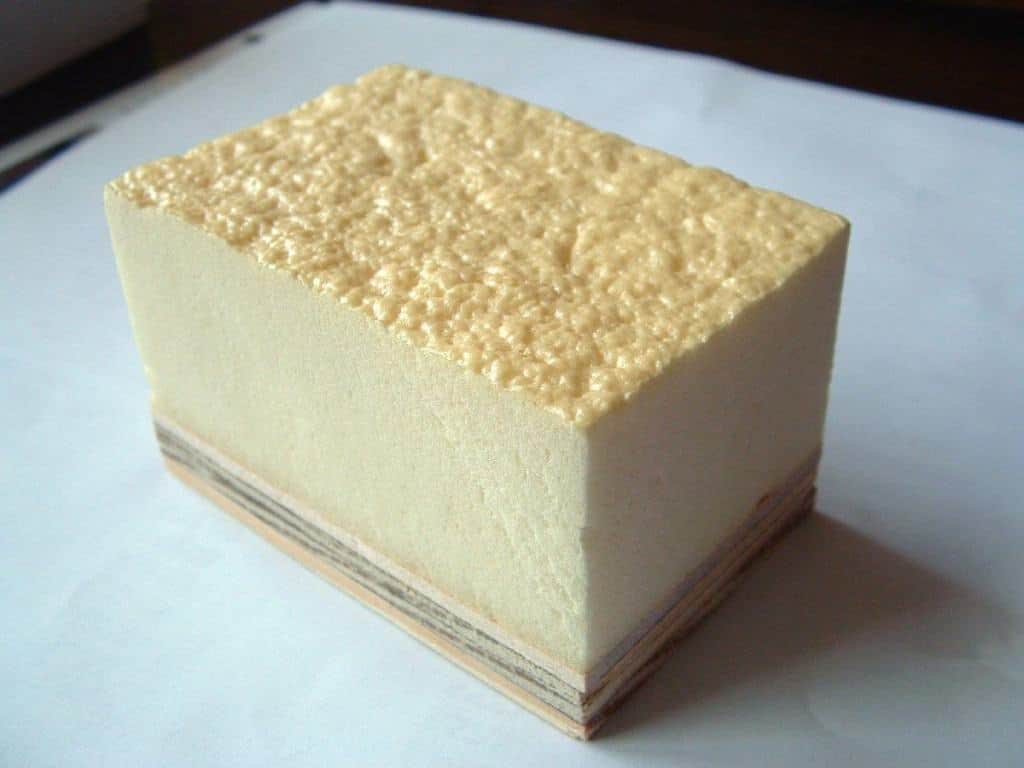

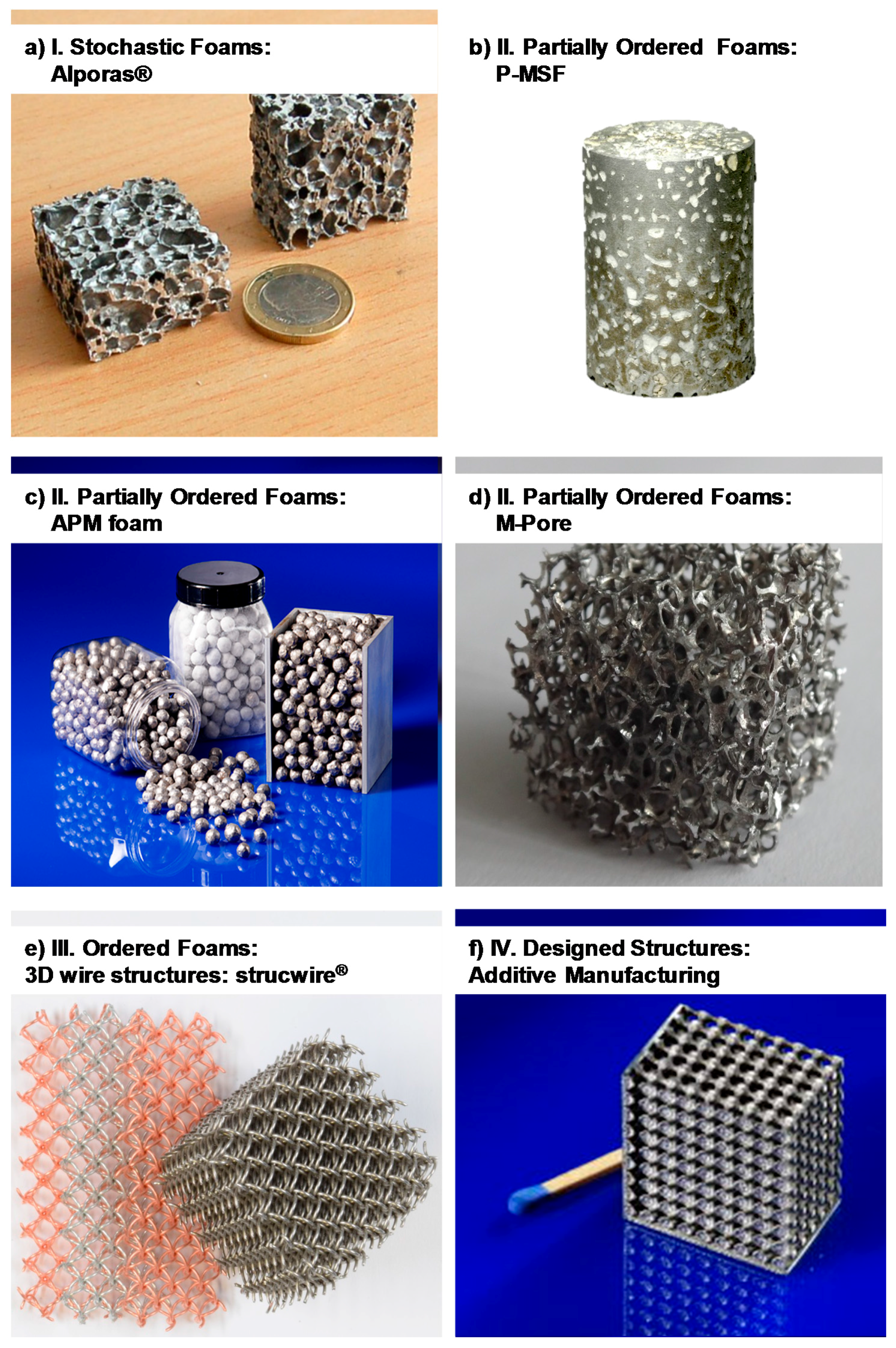

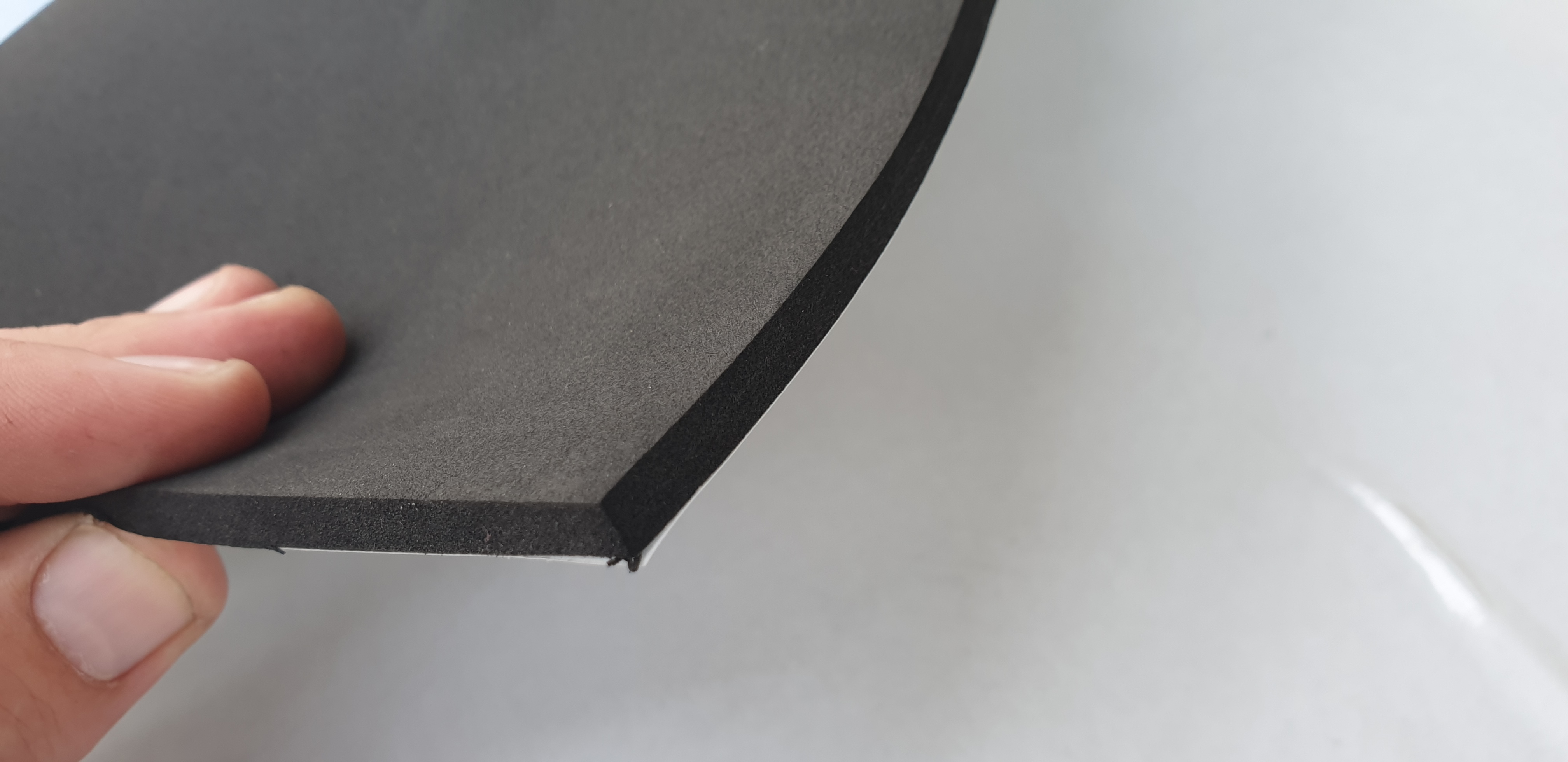

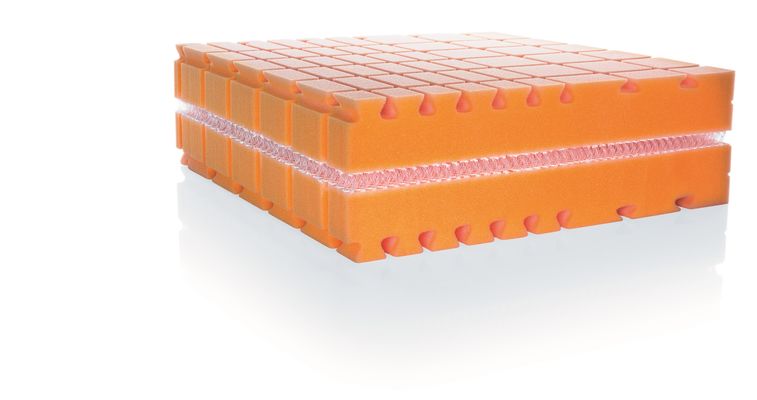

Before we dive into the specific chemicals, it's essential to understand the different types of foam used in mattress production. The most common type is polyurethane foam, which is known for its supportive and comfortable qualities. Other types include latex foam, memory foam, and gel foam, each with its unique properties.Foam Mattress Production

Polyurethane foam is the most widely used material in foam mattress production. It is made by combining two main components - a polyol and an isocyanate. These components react and expand to create the foam that is used in mattresses. The type of polyol and isocyanate used can affect the density and firmness of the foam.Polyurethane Foam

The process of foam manufacturing involves the use of various chemicals, including blowing agents, stabilizers, flame retardants, adhesives, and additives. These chemicals are crucial in creating the foam's properties and ensuring its quality and durability.Foam Manufacturing

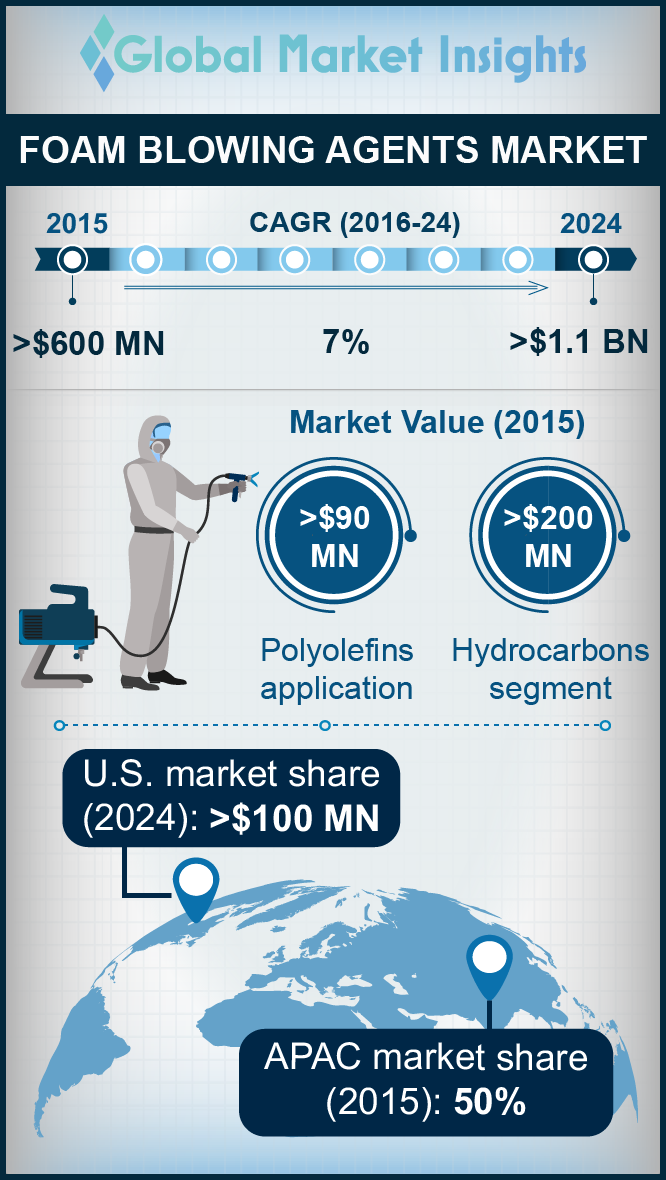

One of the essential chemicals in foam production is blowing agents. These are substances that create gas bubbles within the foam, giving it a cellular structure. This structure is what makes the foam lightweight, soft, and flexible. Common blowing agents used in foam mattresses include water, pentane, and carbon dioxide.Foam Blowing Agents

To ensure the foam maintains its structure and properties, foam stabilizers are added during the production process. These chemicals prevent the foam from collapsing or shrinking over time and help maintain its shape and firmness. They also improve the foam's resistance to wear and tear.Foam Stabilizers

For safety reasons, foam mattresses are required to meet certain fire safety standards. To achieve this, manufacturers add flame retardants to the foam. These chemicals slow down or prevent the spread of fire, reducing the risk of the mattress catching fire. Common flame retardants used include boric acid, melamine, and phosphorus compounds.Foam Flame Retardants

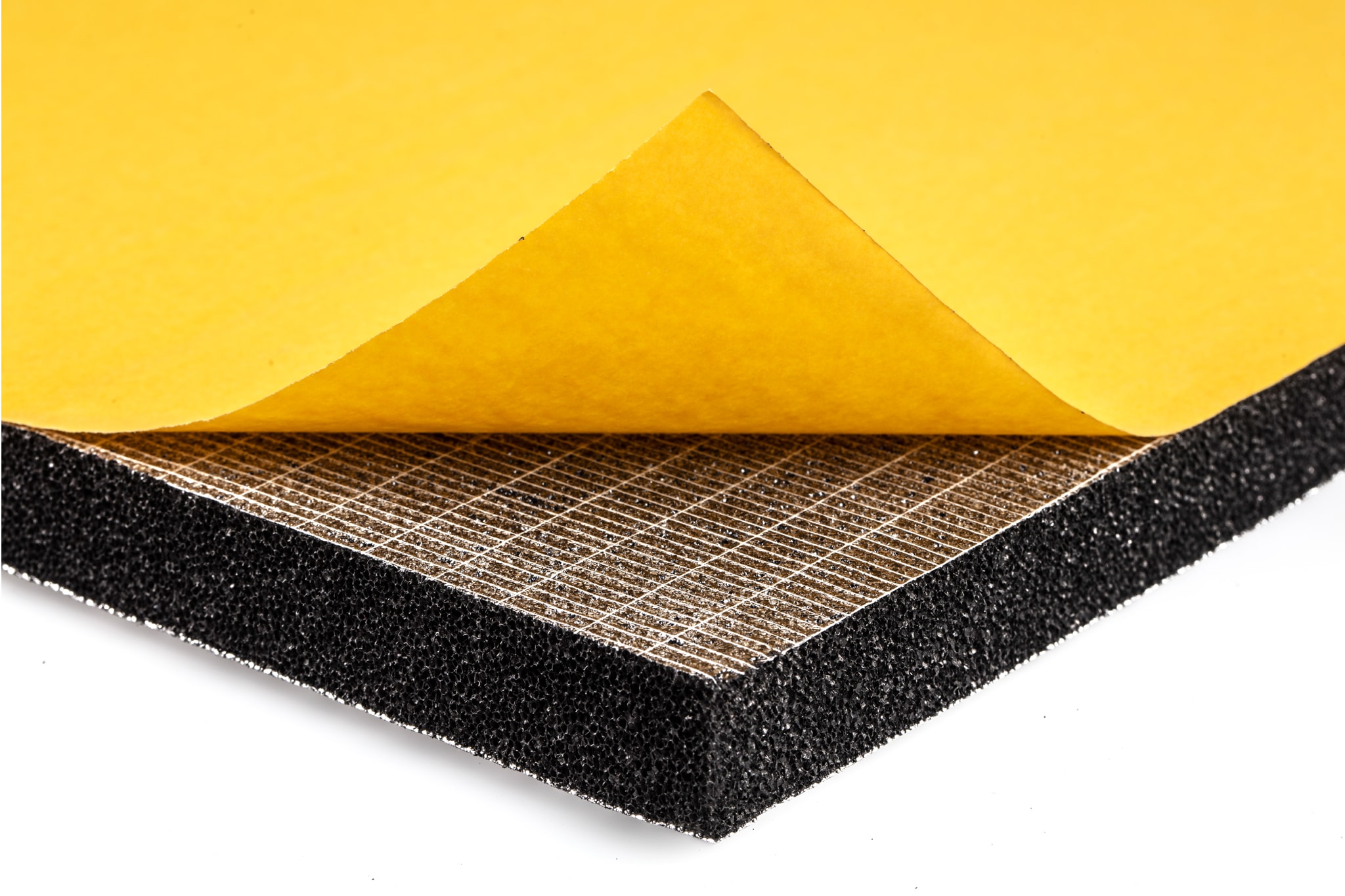

In the production of foam mattresses, adhesives are used to bond different layers of foam together. These adhesives are essential in creating a strong and durable mattress. They also play a role in maintaining the shape and structure of the mattress over time.Foam Adhesives

Finally, foam additives are used to enhance the foam's properties and performance. These can include antioxidants, colorants, and UV stabilizers to improve the foam's lifespan and resistance to external factors such as sunlight and oxidation.Foam Additives

The Benefits of Foam Mattress Making Chemicals in House Design

Creating Comfortable and Durable Beds

When it comes to designing a comfortable and inviting home, the bedroom is often a top priority. After all, it is where we spend a significant portion of our time resting and rejuvenating. As such, the quality of our bed plays a crucial role in ensuring a good night's sleep. This is where foam mattresses come in, and the chemicals used in their production are vital in creating a comfortable and durable bed.

Foam mattresses

are made from a type of foam known as polyurethane foam. This material is created by combining two main components - polyols and isocyanates. These chemicals, when mixed in the right proportions, react to form a foam that is then molded into the desired shape and size. This process allows for the creation of different types of foam mattresses, each with its unique properties and benefits.

The main benefit of using foam mattress making chemicals

is their ability to provide support and comfort. Foam mattresses are known for their ability to conform to the body's shape, providing optimal support and pressure relief. This is especially beneficial for those with back or joint pain, as the foam helps to distribute body weight evenly, reducing pressure points and promoting better spinal alignment.

Moreover, foam mattress making chemicals also contribute to the durability of the mattress. The use of high-quality materials and precise mixing of chemicals results in a foam that is resilient and long-lasting. This means that your mattress will maintain its shape and support for many years, making it a worthwhile investment for your home.

When it comes to designing a comfortable and inviting home, the bedroom is often a top priority. After all, it is where we spend a significant portion of our time resting and rejuvenating. As such, the quality of our bed plays a crucial role in ensuring a good night's sleep. This is where foam mattresses come in, and the chemicals used in their production are vital in creating a comfortable and durable bed.

Foam mattresses

are made from a type of foam known as polyurethane foam. This material is created by combining two main components - polyols and isocyanates. These chemicals, when mixed in the right proportions, react to form a foam that is then molded into the desired shape and size. This process allows for the creation of different types of foam mattresses, each with its unique properties and benefits.

The main benefit of using foam mattress making chemicals

is their ability to provide support and comfort. Foam mattresses are known for their ability to conform to the body's shape, providing optimal support and pressure relief. This is especially beneficial for those with back or joint pain, as the foam helps to distribute body weight evenly, reducing pressure points and promoting better spinal alignment.

Moreover, foam mattress making chemicals also contribute to the durability of the mattress. The use of high-quality materials and precise mixing of chemicals results in a foam that is resilient and long-lasting. This means that your mattress will maintain its shape and support for many years, making it a worthwhile investment for your home.

Improving Indoor Air Quality

Another significant advantage of foam mattress making chemicals is their contribution to indoor air quality. Traditional mattresses are known to emit volatile organic compounds (VOCs), which can cause respiratory issues and allergic reactions. However, foam mattresses made with high-quality chemicals have low VOC emissions, making them a healthier option for your home.

In addition to this, foam mattress chemicals are also

environmentally friendly

. Most foam manufacturers use eco-friendly materials and processes, reducing their impact on the environment. This makes foam mattresses a more sustainable and responsible choice for those looking to design an eco-friendly home.

In conclusion, foam mattress making chemicals are crucial in creating comfortable, durable, and eco-friendly beds. Their ability to provide support, improve indoor air quality, and contribute to sustainability makes them an excellent choice for any house design. With their wide range of benefits and versatility, foam mattresses are a worthy addition to any bedroom.

Another significant advantage of foam mattress making chemicals is their contribution to indoor air quality. Traditional mattresses are known to emit volatile organic compounds (VOCs), which can cause respiratory issues and allergic reactions. However, foam mattresses made with high-quality chemicals have low VOC emissions, making them a healthier option for your home.

In addition to this, foam mattress chemicals are also

environmentally friendly

. Most foam manufacturers use eco-friendly materials and processes, reducing their impact on the environment. This makes foam mattresses a more sustainable and responsible choice for those looking to design an eco-friendly home.

In conclusion, foam mattress making chemicals are crucial in creating comfortable, durable, and eco-friendly beds. Their ability to provide support, improve indoor air quality, and contribute to sustainability makes them an excellent choice for any house design. With their wide range of benefits and versatility, foam mattresses are a worthy addition to any bedroom.