The Dunlop process is a method of producing latex foam used in the manufacturing of latex mattresses. It was first developed in 1929 by John Boyd Dunlop and has since become a popular and reliable method for creating high-quality latex mattresses.What is the Dunlop Process for Latex Mattresses?

There are many benefits to choosing a latex mattress made with the Dunlop process. One of the biggest advantages is the durability of the mattress. The Dunlop process creates a denser and more resilient foam, making the mattress last longer compared to other types of mattresses. Additionally, latex mattresses made with the Dunlop process provide excellent support and comfort. The foam is known for its ability to contour to the body, relieving pressure points and promoting proper spinal alignment. This can lead to a more restful and comfortable sleep. Furthermore, latex mattresses made with the Dunlop process are hypoallergenic and resistant to dust mites, mold, and mildew. This makes them a great option for those with allergies or respiratory issues.Benefits of Choosing a Latex Mattress Made with the Dunlop Process

The easiest way to identify a latex mattress made with the Dunlop process is to look for the GOLS (Global Organic Latex Standard) certification. This certification ensures that the latex used in the mattress is made through the Dunlop process and is of high quality. You can also look for the density and firmness levels of the mattress. Latex mattresses made with the Dunlop process are typically denser and firmer compared to those made with the Talalay process.How to Identify a Latex Mattress Made with the Dunlop Process

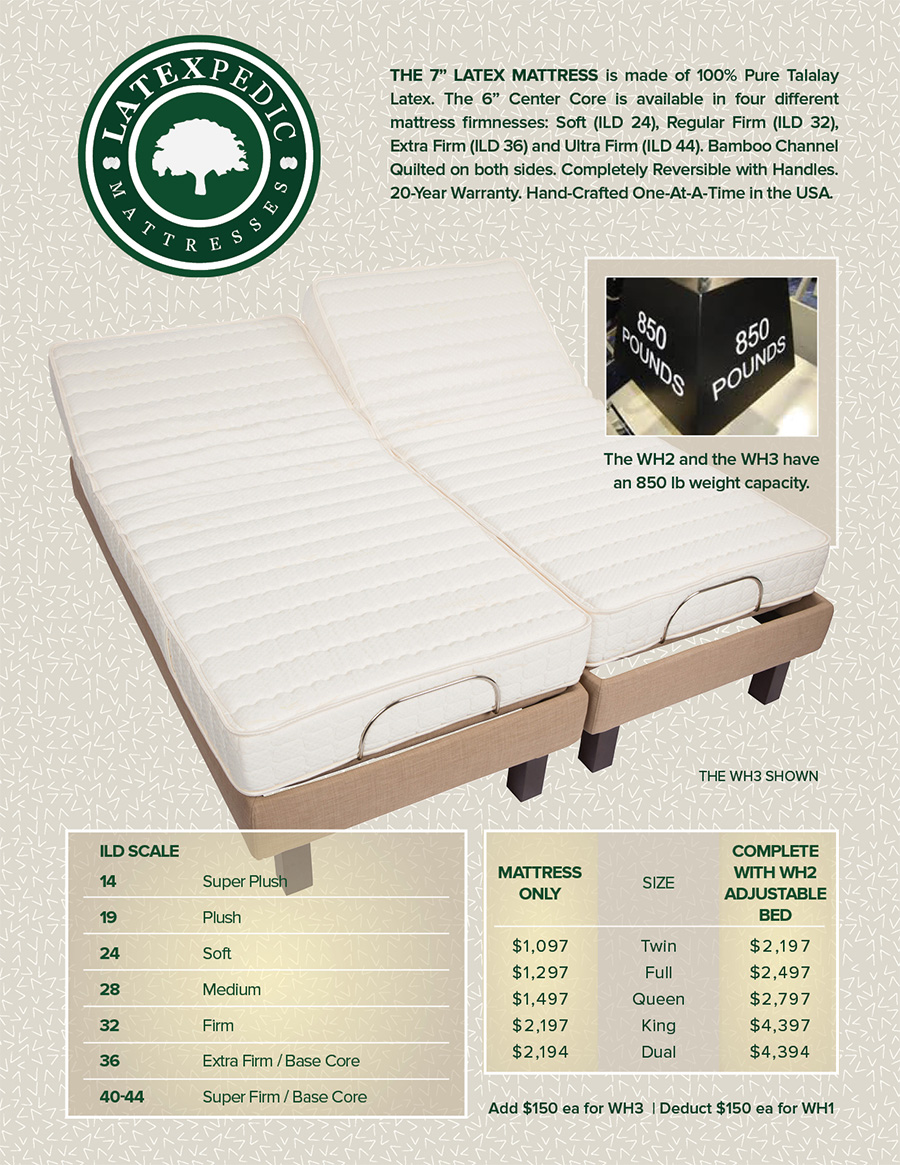

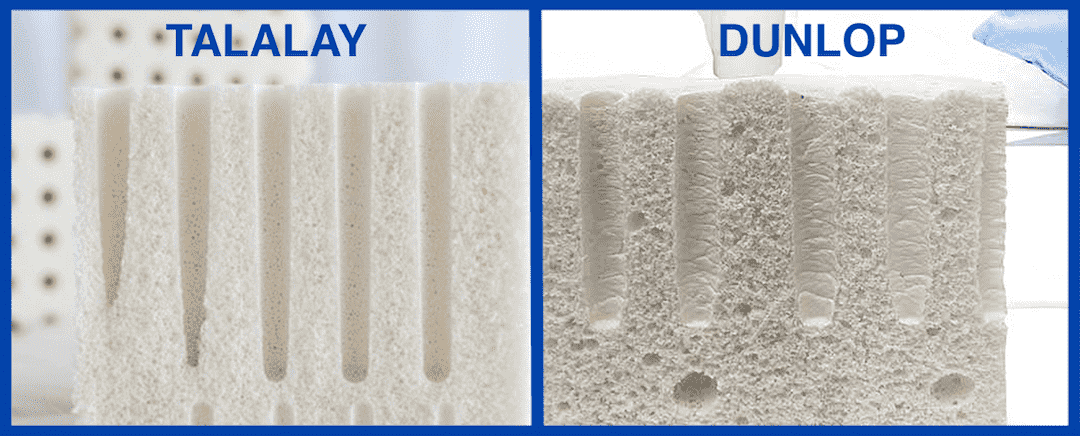

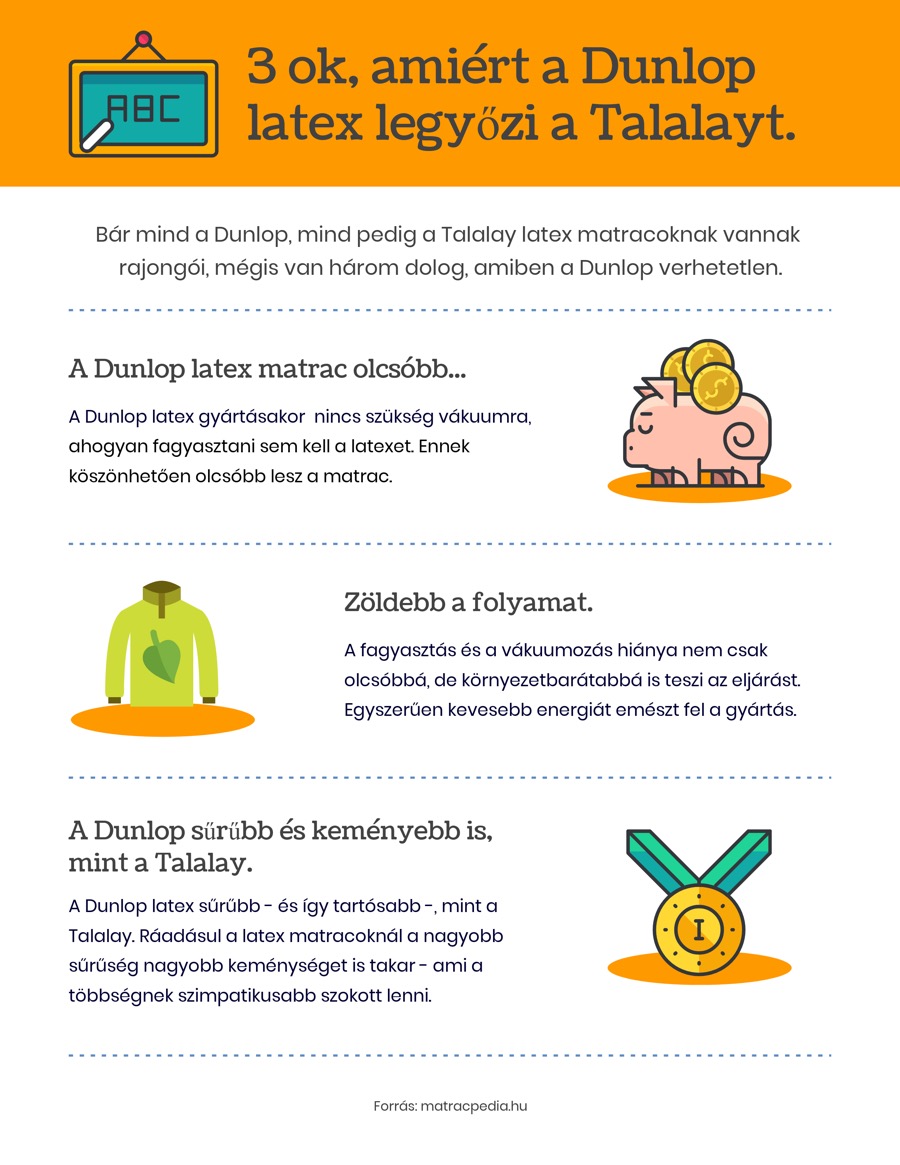

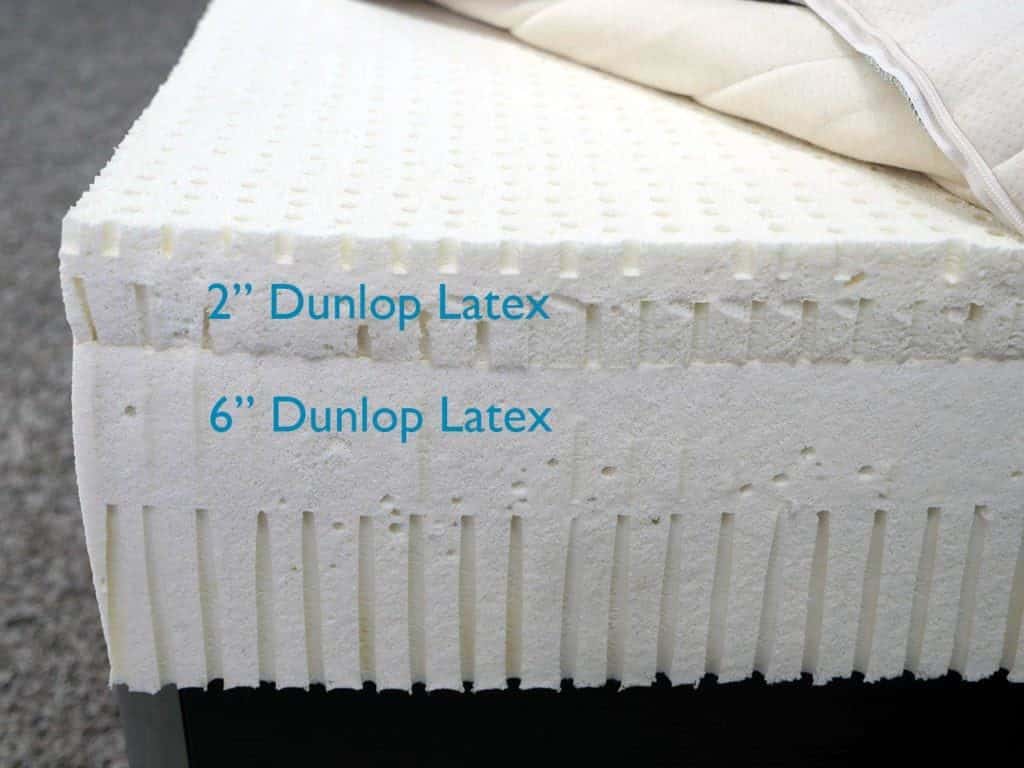

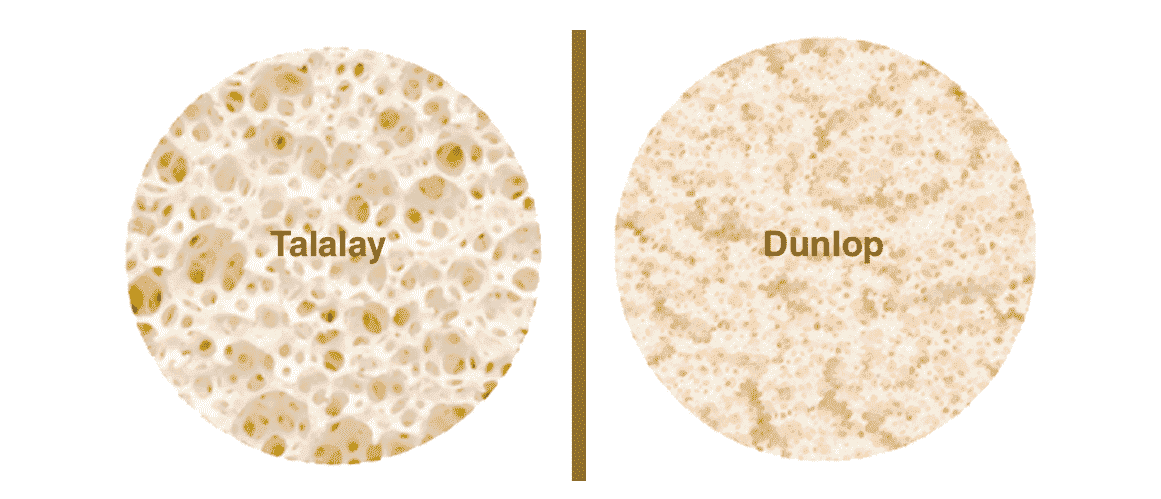

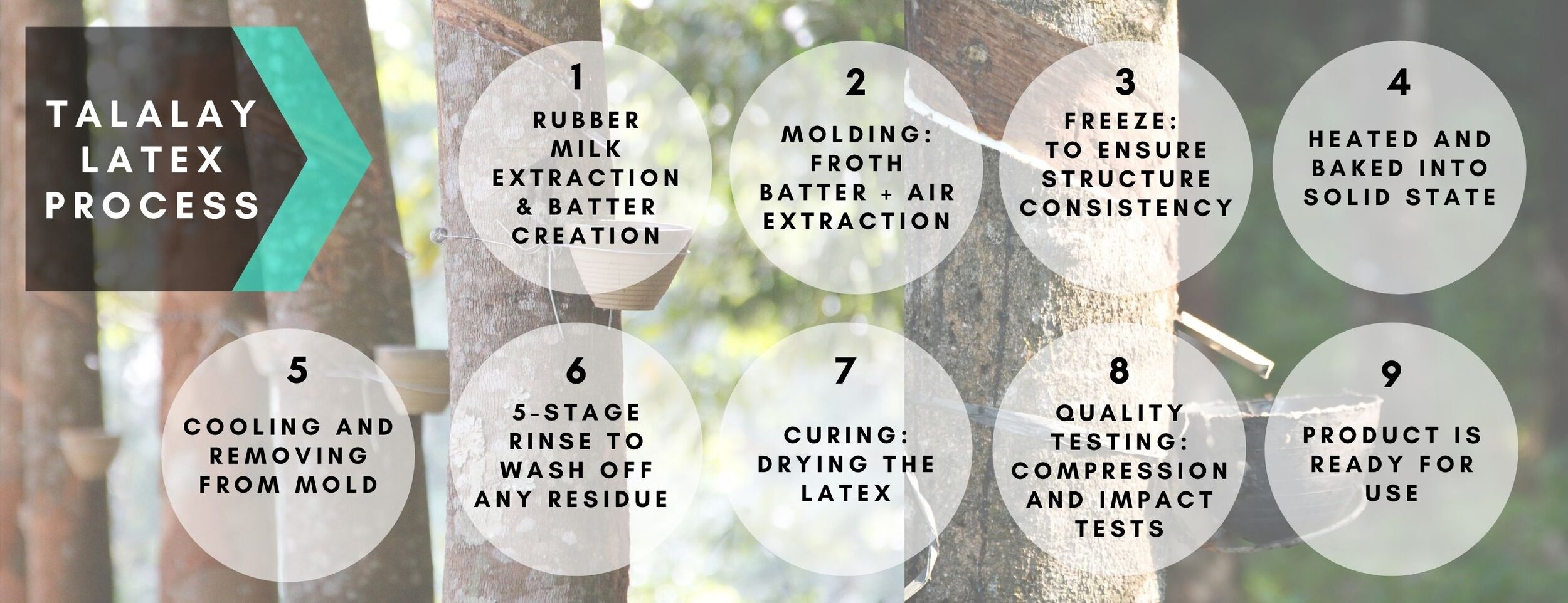

While the Dunlop and Talalay processes both produce high-quality latex foam, there are some key differences between the two methods. The Dunlop process creates a denser and firmer foam, while the Talalay process produces a softer and more consistent foam. Additionally, the Dunlop process does not use a vacuum to distribute the latex, resulting in a slightly uneven distribution of particles. On the other hand, the Talalay process uses a vacuum to evenly distribute the particles, resulting in a more consistent foam. Another difference between the two processes is the amount of air trapped in the foam. The Dunlop process creates a foam with larger air pockets, while the Talalay process produces a foam with smaller air pockets.Understanding the Differences Between the Dunlop and Talalay Latex Processes

The Dunlop process is known for its eco-friendly aspects, making it a popular choice among environmentally-conscious consumers. The process uses natural materials such as rubber tree sap and does not require the use of harmful chemicals. In addition, the Dunlop process produces very little waste. Any excess latex can be recycled and used in other products, making it a sustainable option for mattress production.Eco-Friendly Aspects of the Dunlop Process for Latex Mattresses

When it comes to durability, latex mattresses made with the Dunlop process have an edge over those made with the Talalay process. The denser and firmer foam created by the Dunlop process is more resilient and can withstand regular use for a longer period of time. Furthermore, the Dunlop process does not use any chemical additives, making the foam more natural and less prone to breaking down over time.Comparing the Durability of Dunlop and Talalay Latex Mattresses

The Dunlop process has a significant impact on the firmness of latex mattresses. As mentioned earlier, the process creates a denser and firmer foam compared to the Talalay process. This means that mattresses made with the Dunlop process are typically firmer and provide more support. However, the firmness of a latex mattress also depends on the type of latex used and the overall design of the mattress. So, while the Dunlop process does play a role in the firmness of a latex mattress, it is not the only factor.How the Dunlop Process Affects the Firmness of Latex Mattresses

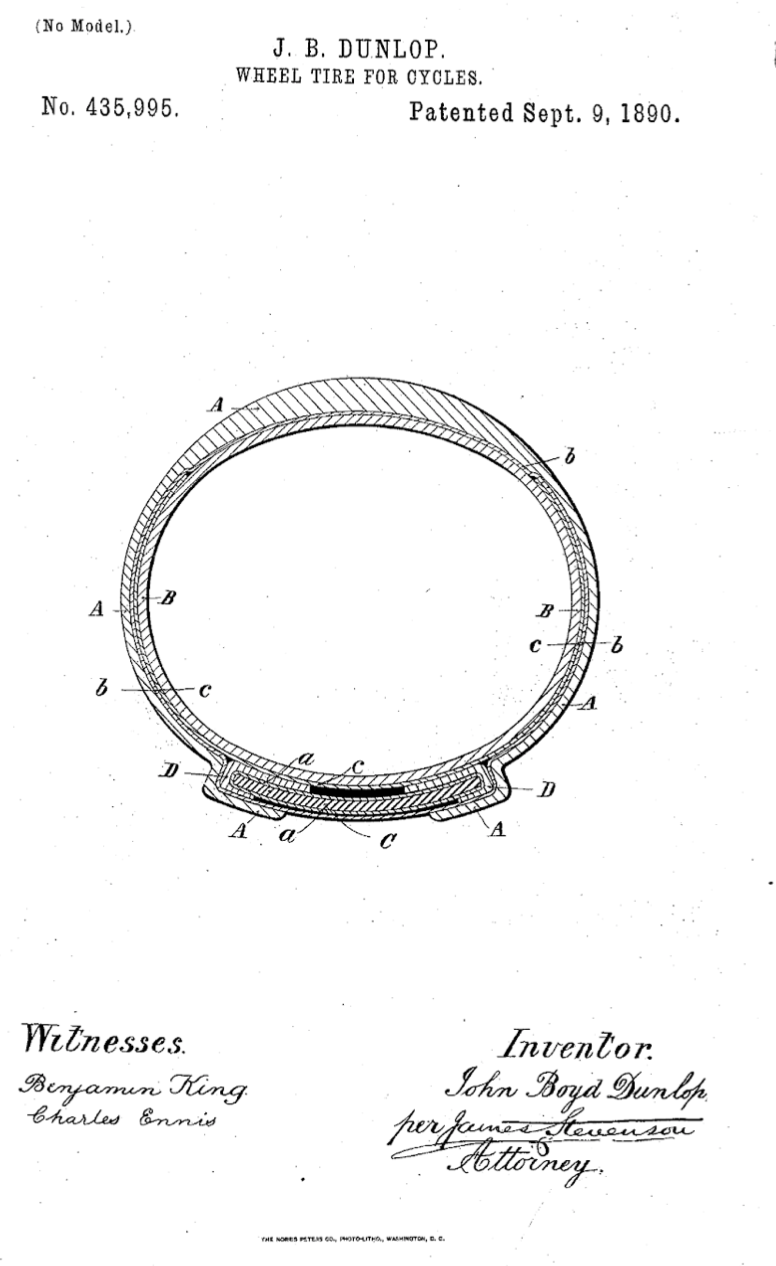

The Dunlop process has a rich history dating back to 1929 when it was first developed by John Boyd Dunlop. It was originally used to create latex rubber for car tires, but it was later adapted for use in the production of latex foam for mattresses. Since then, the Dunlop process has continued to evolve and improve, becoming a widely-used and trusted method for creating high-quality latex mattresses.Exploring the History of the Dunlop Process for Latex Mattresses

Heat plays a crucial role in the Dunlop process for latex mattresses. The process involves heating the rubber tree sap to a high temperature, causing it to solidify and form a foam. The heat also helps to distribute the particles evenly, resulting in a more consistent foam. However, the heat used in the Dunlop process is not excessive, making it a safe and eco-friendly method of producing latex foam.The Role of Heat in the Dunlop Process for Latex Mattresses

To ensure the longevity of your latex mattress made with the Dunlop process, there are a few maintenance tips to keep in mind. Firstly, it is important to rotate your mattress regularly to prevent uneven wear. Additionally, spot cleaning any spills or stains immediately can help prevent damage to the foam. Furthermore, avoid exposing the mattress to direct sunlight or excessive heat, as this can cause the foam to break down over time. And if you need to move the mattress, it is best to avoid bending or folding it, as this can cause damage to the foam layers. In conclusion, the Dunlop process is a tried and true method for creating high-quality latex mattresses. Its eco-friendly aspects, durability, and comfort make it a popular choice among consumers. So, if you're in the market for a new mattress, consider choosing one made with the Dunlop process for a comfortable and sustainable sleep experience.Tips for Maintaining a Latex Mattress Made with the Dunlop Process

The Benefits of Choosing a Latex Mattress Made with the Dunlop Process

What is the Dunlop Process?

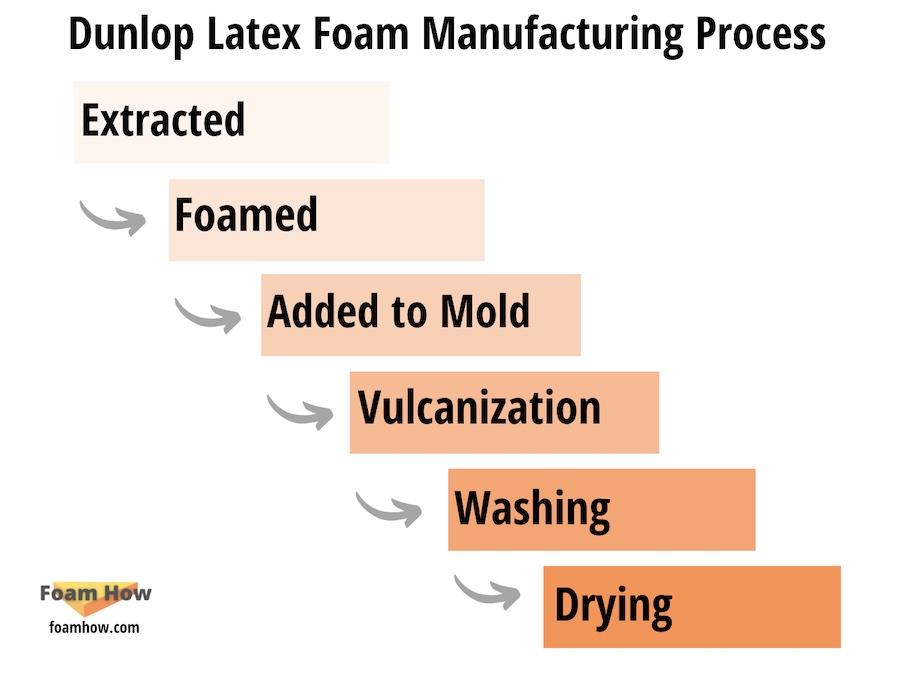

The Dunlop process is a method of manufacturing latex foam, which is a popular material used in mattresses. This process was developed in the early 1900s and is still widely used today due to its efficiency and effectiveness in producing high-quality latex foam.

Latex mattresses

made with the Dunlop process start with the extraction of

natural latex

from rubber trees. The sap is then mixed with additives such as foaming agents and vulcanizing agents before being whipped into a frothy consistency. This mixture is then poured into a mold and heated, causing the latex to form a solid foam. The foam is then washed and dried before being cut to size and used in mattresses.

The Dunlop process is a method of manufacturing latex foam, which is a popular material used in mattresses. This process was developed in the early 1900s and is still widely used today due to its efficiency and effectiveness in producing high-quality latex foam.

Latex mattresses

made with the Dunlop process start with the extraction of

natural latex

from rubber trees. The sap is then mixed with additives such as foaming agents and vulcanizing agents before being whipped into a frothy consistency. This mixture is then poured into a mold and heated, causing the latex to form a solid foam. The foam is then washed and dried before being cut to size and used in mattresses.

The Benefits of Latex Mattresses Made with the Dunlop Process

There are several benefits to choosing a

latex mattress

made with the Dunlop process over other types of mattresses.

Durability:

Latex foam made with the Dunlop process is known for its durability and resilience. It can withstand frequent use and is less likely to sag or lose its shape over time compared to other mattress materials.

Support and Comfort:

The Dunlop process creates a dense and firm latex foam, which provides excellent support for the body. This makes it an ideal choice for those with back pain or other body aches. Additionally, the foam is also able to conform to the body's curves, providing a comfortable and pressure-relieving sleep surface.

Natural and Hypoallergenic:

Latex foam made with the Dunlop process is typically made from

100% natural latex

, which is derived from rubber trees. This makes it a more environmentally friendly and sustainable option compared to synthetic materials. It is also naturally hypoallergenic, making it a great choice for those with allergies or sensitivities.

Breathability:

Latex foam has an open-cell structure, allowing for better air circulation and breathability. This helps regulate body temperature and prevents overheating during sleep, making it a great choice for hot sleepers.

There are several benefits to choosing a

latex mattress

made with the Dunlop process over other types of mattresses.

Durability:

Latex foam made with the Dunlop process is known for its durability and resilience. It can withstand frequent use and is less likely to sag or lose its shape over time compared to other mattress materials.

Support and Comfort:

The Dunlop process creates a dense and firm latex foam, which provides excellent support for the body. This makes it an ideal choice for those with back pain or other body aches. Additionally, the foam is also able to conform to the body's curves, providing a comfortable and pressure-relieving sleep surface.

Natural and Hypoallergenic:

Latex foam made with the Dunlop process is typically made from

100% natural latex

, which is derived from rubber trees. This makes it a more environmentally friendly and sustainable option compared to synthetic materials. It is also naturally hypoallergenic, making it a great choice for those with allergies or sensitivities.

Breathability:

Latex foam has an open-cell structure, allowing for better air circulation and breathability. This helps regulate body temperature and prevents overheating during sleep, making it a great choice for hot sleepers.

In Conclusion

Choosing a latex mattress made with the Dunlop process offers numerous benefits, from its durability and support to its natural and hypoallergenic properties. So if you're looking for a comfortable, eco-friendly, and long-lasting mattress, consider choosing one made with the Dunlop process.

Choosing a latex mattress made with the Dunlop process offers numerous benefits, from its durability and support to its natural and hypoallergenic properties. So if you're looking for a comfortable, eco-friendly, and long-lasting mattress, consider choosing one made with the Dunlop process.