The mattress industry has undergone significant technological advancements in recent years, with the introduction of modern manufacturing machines. Among these, spring mattress manufacturing machines have played a crucial role in streamlining the production process and improving the overall quality of mattresses. In this article, we will take a closer look at the top 10 MAIN_spring mattress manufacturing machines that have revolutionized the industry.Introduction:

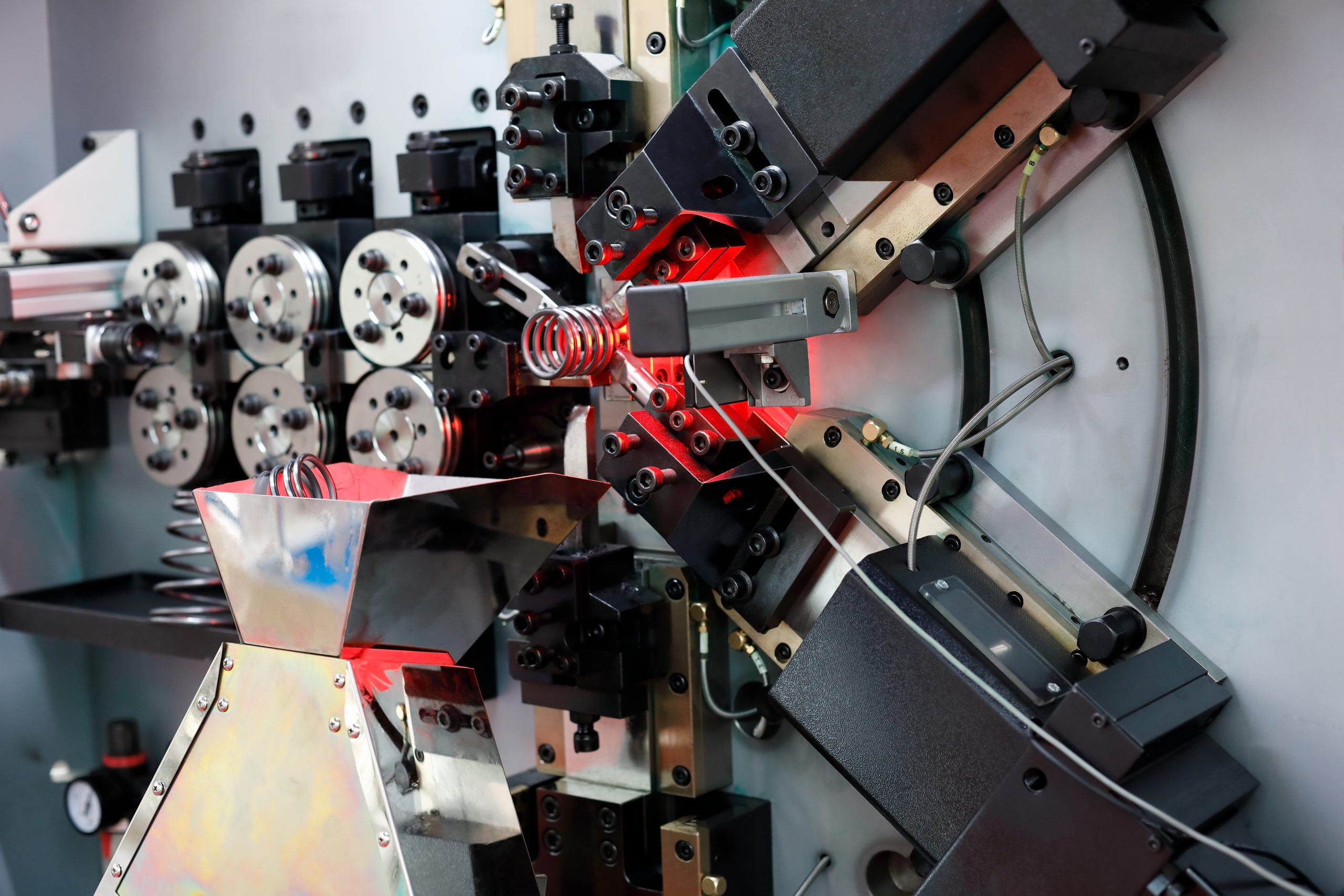

The spring coiling machine is a vital piece of equipment in the production of spring mattresses. It is used to create the individual springs that make up the core of the mattress. This machine uses high-quality steel wire to create coils of various sizes and shapes, which are then placed into the mattress frame. The precision and speed of this machine ensure consistent and durable springs for superior mattress support and longevity.1. Spring Coiling Machine

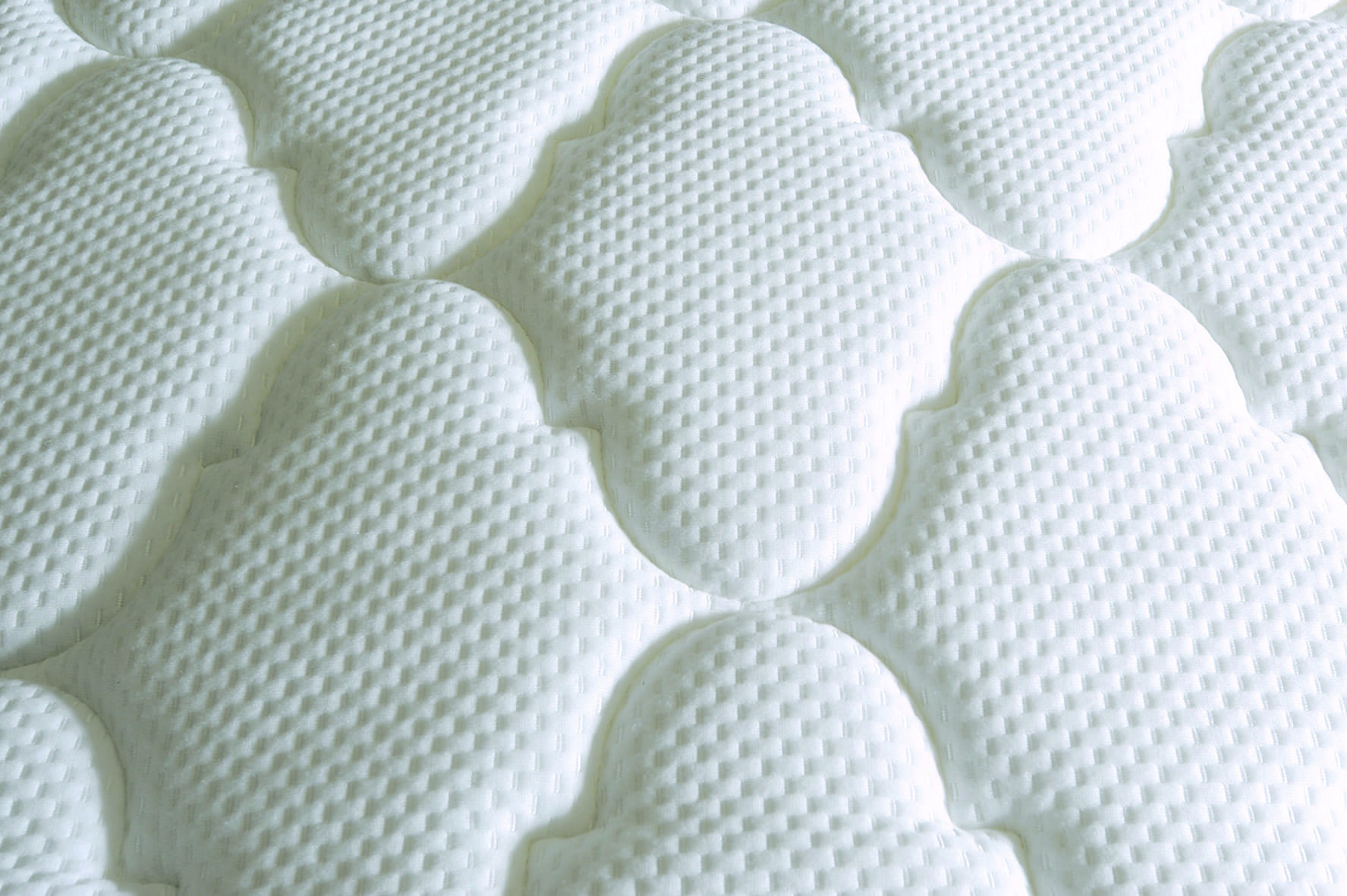

The mattress quilting machine is responsible for creating the intricate patterns and designs on the top layer of the mattress. It uses multiple needles and threads to stitch together the top fabric layer with the underlying layers, creating a quilted effect. This machine allows for customization and adds aesthetic appeal to the mattress, making it more attractive to customers.2. Mattress Quilting Machine

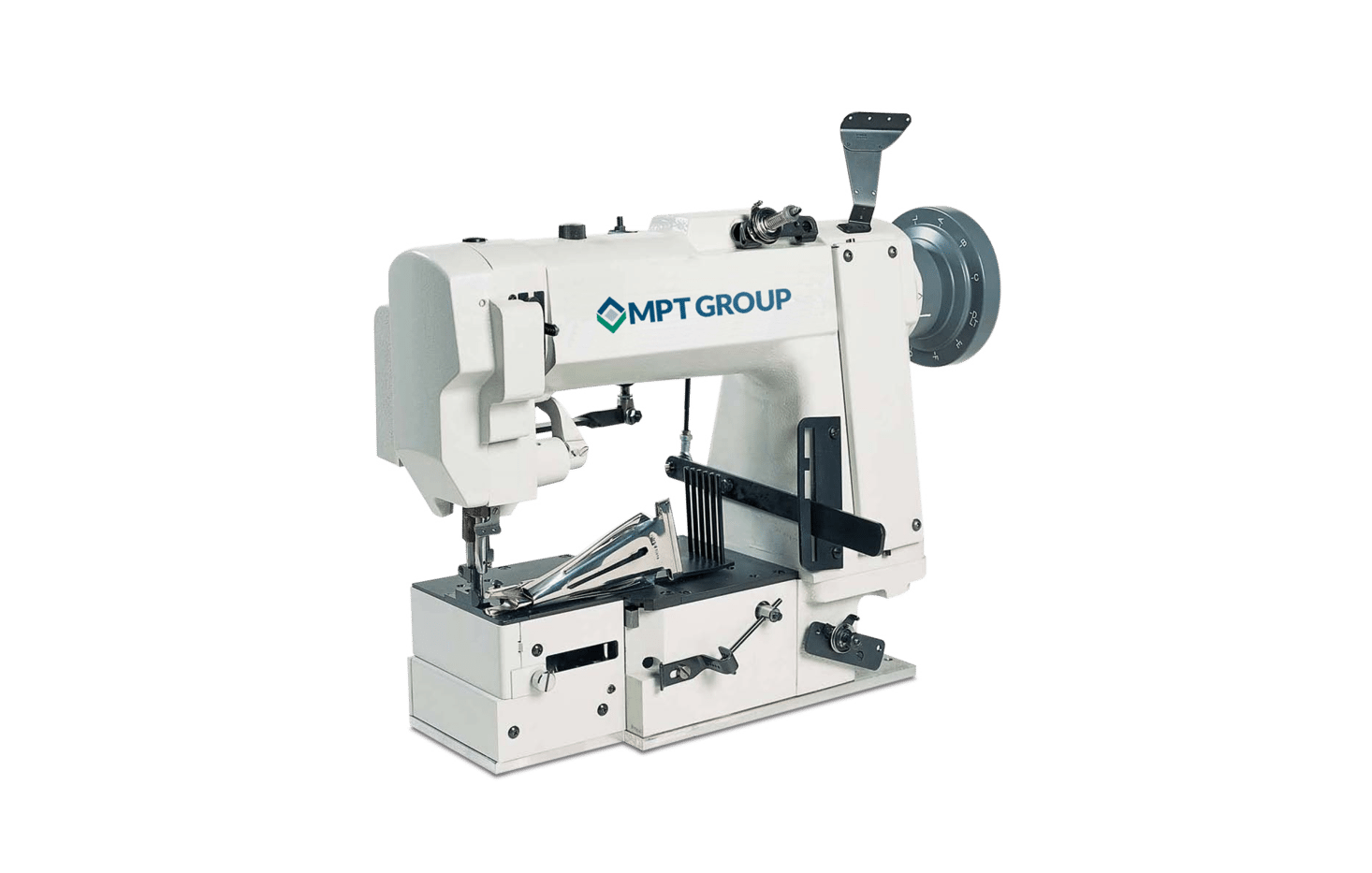

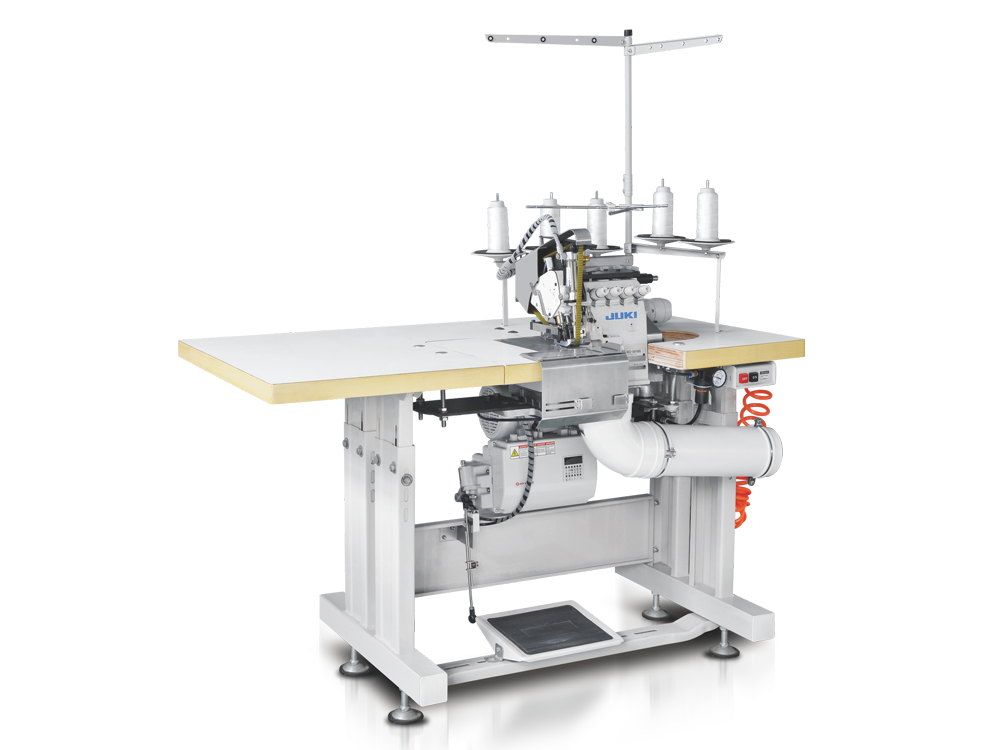

The border sewing machine is used to stitch the border of the mattress, which holds all the layers and springs together. This machine uses high-speed sewing needles and threads to create a strong and seamless border, ensuring the durability and stability of the mattress. It also allows for different border designs and patterns, adding to the overall aesthetic appeal of the mattress.3. Mattress Border Sewing Machine

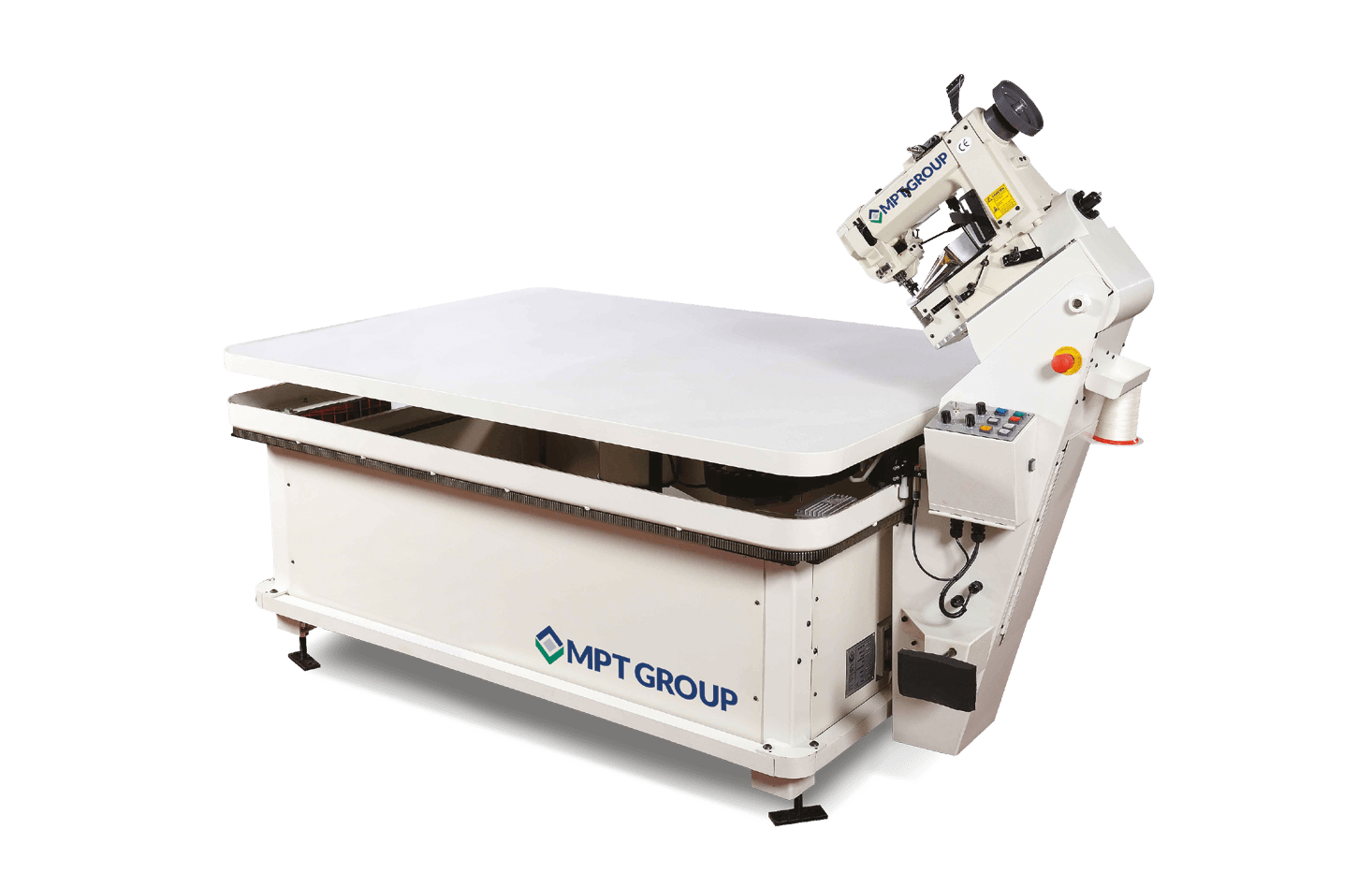

The tape edge machine is responsible for attaching the top and bottom fabric layers of the mattress to the border, creating a smooth and neat finish. It uses a hot-melt adhesive to bond the layers together, ensuring a strong and long-lasting seal. This machine also allows for customization, with the ability to add branded tape or labels to the mattress.4. Mattress Tape Edge Machine

The flanging machine is used to attach the side panels of the mattress to the border, creating a neat and seamless finish. It uses multiple needles and threads to stitch the fabric layers together, ensuring a strong and durable bond. This machine also allows for the customization of side panels, adding to the overall design and branding of the mattress.5. Mattress Flanging Machine

The roll packing machine is responsible for compressing and packaging the finished mattress for transportation and storage. It uses a vacuum system to compress the mattress into a compact roll, making it easier to handle and transport. This machine also ensures that the mattress maintains its shape and support, even after being compressed, ensuring customer satisfaction upon delivery.6. Mattress Roll Packing Machine

The gluing machine is used to apply adhesive to different mattress components, such as foam layers, fabric, and springs. It ensures a strong and secure bond between the layers, providing durability and stability to the mattress. This machine also allows for precise and controlled application of adhesive, reducing waste and ensuring a consistent quality of the final product.7. Mattress Gluing Machine

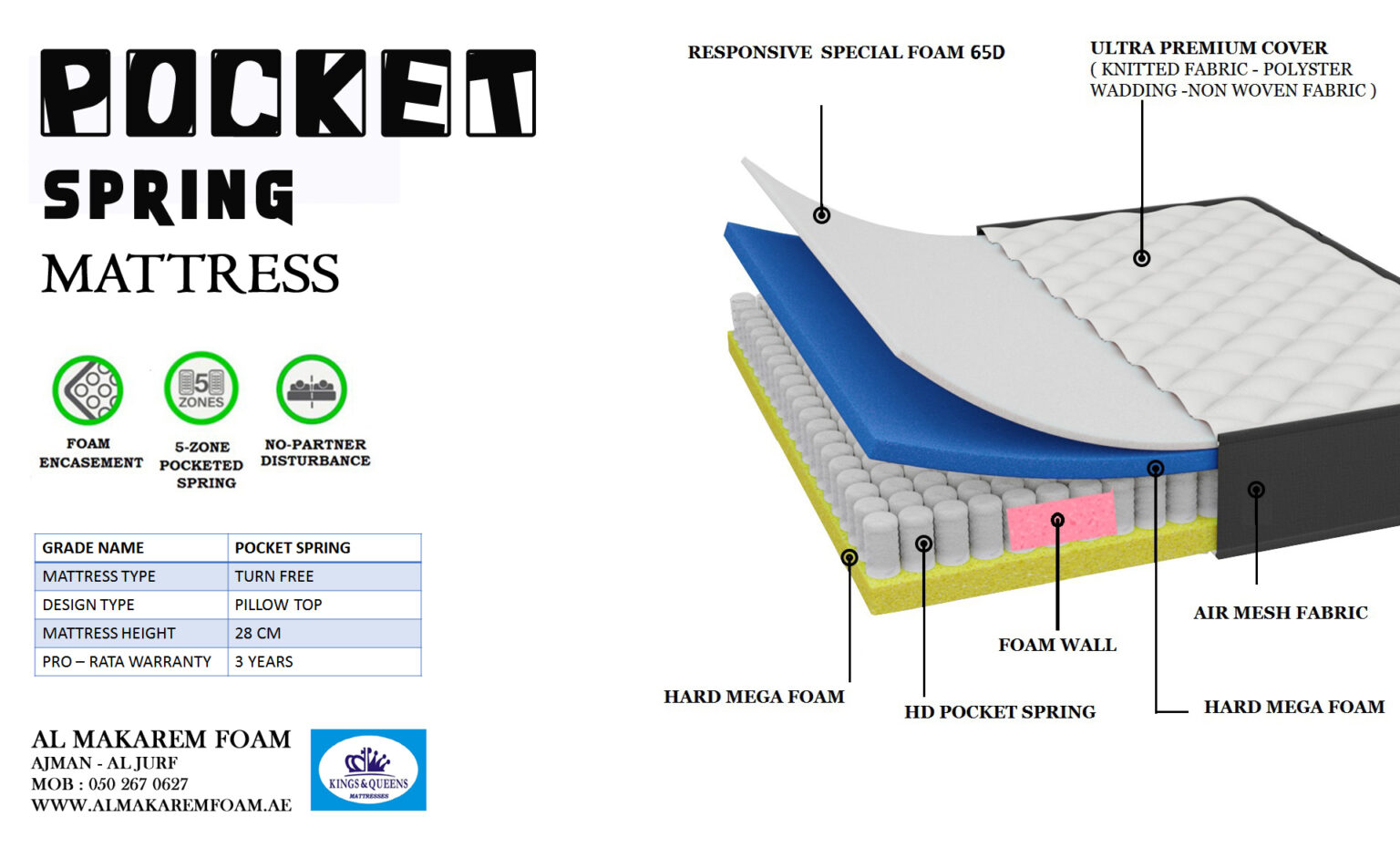

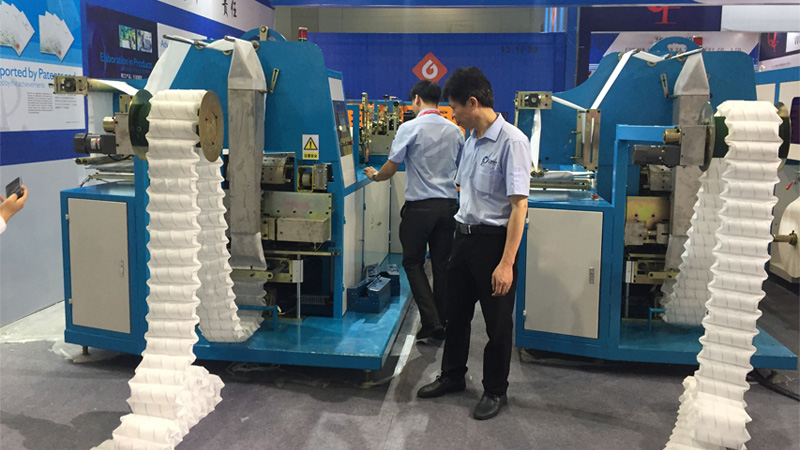

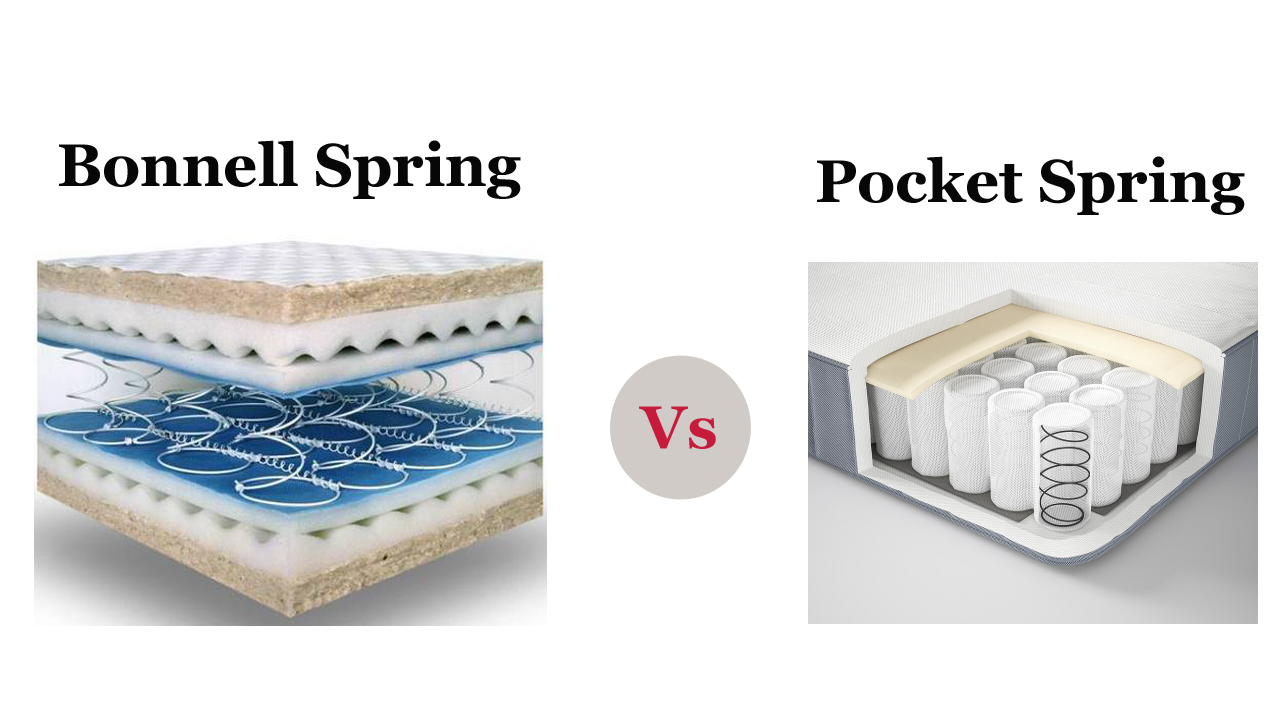

The pocket spring machine is responsible for creating individual springs encased in fabric pockets, which are then used in high-end pocket spring mattresses. This machine uses high-quality materials and advanced technology to produce springs of various sizes and shapes, providing superior support and comfort to the sleeper. It also allows for customization of pocket spring size and firmness, catering to different customer preferences.8. Mattress Pocket Spring Machine

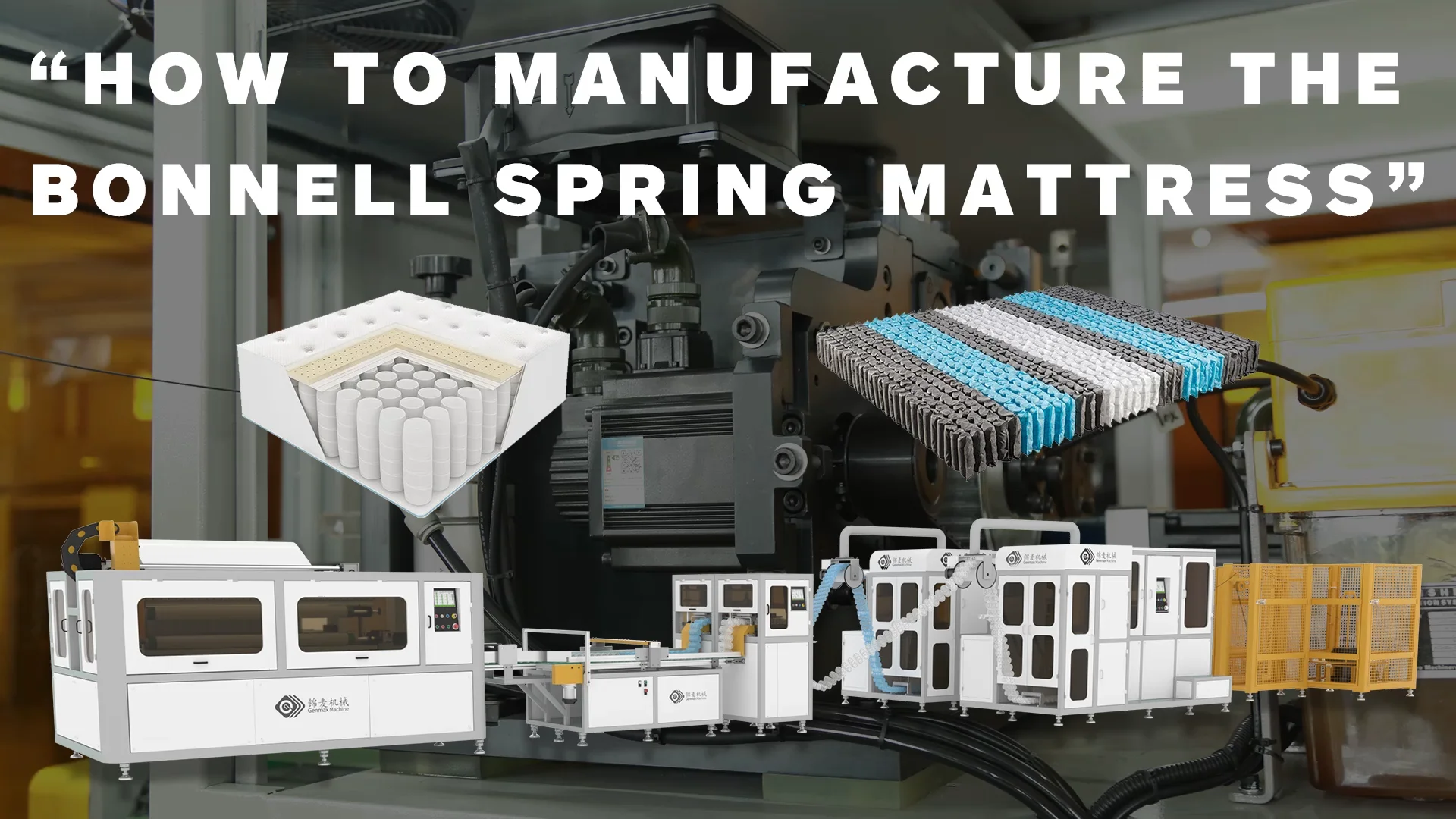

The Bonnell spring machine is used to create the traditional hourglass-shaped springs commonly found in innerspring mattresses. It uses high-quality steel wire to produce durable and resilient springs, providing excellent support and comfort to the sleeper. This machine also allows for customization of spring size and shape, catering to different mattress designs and firmness levels.9. Mattress Bonnell Spring Machine

How Spring Mattress Manufacturing Machines Are Revolutionizing the House Design Industry

When it comes to house design, one of the most important elements is the mattress. A good mattress can make all the difference in getting a good night's sleep and feeling well-rested in the morning. With advancements in technology, the traditional way of making mattresses has been replaced by modern spring mattress manufacturing machines. These machines have completely revolutionized the mattress industry, providing various benefits such as increased efficiency, improved quality, and cost-effectiveness.

The Traditional Way of Making Mattresses

In the past, mattresses were typically made by hand, using a combination of natural materials such as wool, cotton, and feathers. The process was time-consuming and labor-intensive, with each mattress taking several days to complete. This made mattresses expensive, and only the wealthy could afford them.

Eventually, the process was modernized with the introduction of machines that could compress and roll the materials to create a more uniform and compact mattress. However, these machines still required a significant amount of manual labor, and the quality of the mattresses produced was not consistent.

The Advancements in Spring Mattress Manufacturing Machines

With the introduction of spring mattress manufacturing machines, the process of making mattresses has been completely transformed. These machines use advanced technology to produce high-quality mattresses in a fraction of the time it would take to make them by hand. They are equipped with computerized controls and sensors that ensure precision and consistency in the manufacturing process.

The machines are also capable of producing a wide range of mattress sizes and types, from single to king-sized, and from memory foam to hybrid mattresses. This allows for more customization and caters to the diverse needs and preferences of customers.

The Benefits of Spring Mattress Manufacturing Machines

The use of spring mattress manufacturing machines has brought numerous benefits to the house design industry. Firstly, it has increased efficiency in the manufacturing process, reducing the time and labor required to make a mattress. This has also led to a decrease in production costs, making mattresses more affordable for the general public.

Furthermore, the use of these machines has improved the quality of mattresses. The computerized controls and sensors ensure that each mattress is made with precision and consistency, resulting in a more durable and comfortable product. This has led to increased customer satisfaction and loyalty.

In conclusion, spring mattress manufacturing machines have revolutionized the house design industry by providing a more efficient, cost-effective, and high-quality way of making mattresses. With their advanced technology and capabilities, these machines have become an essential tool in the production of mattresses, catering to the ever-changing needs and demands of customers.

:max_bytes(150000):strip_icc()/_hero_4109254-feathertop-5c7d415346e0fb0001a5f085.jpg)