Sealy is a well-known and trusted brand in the mattress industry, and for good reason. Their mattresses are carefully crafted using a unique and precise manufacturing process that ensures comfort, support, and quality. In this article, we will take a closer look at the top 10 steps involved in the Sealy mattress manufacturing process.Sealy Mattress Manufacturing Process

Before we dive into the specifics of the Sealy mattress manufacturing process, it's important to understand the general steps involved in making a mattress. The process typically starts with designing and testing the mattress, followed by sourcing and preparing the materials, assembling the mattress, and finally, quality control and packaging. Now, let's explore how Sealy puts their own spin on this process.How Sealy Mattresses are Made

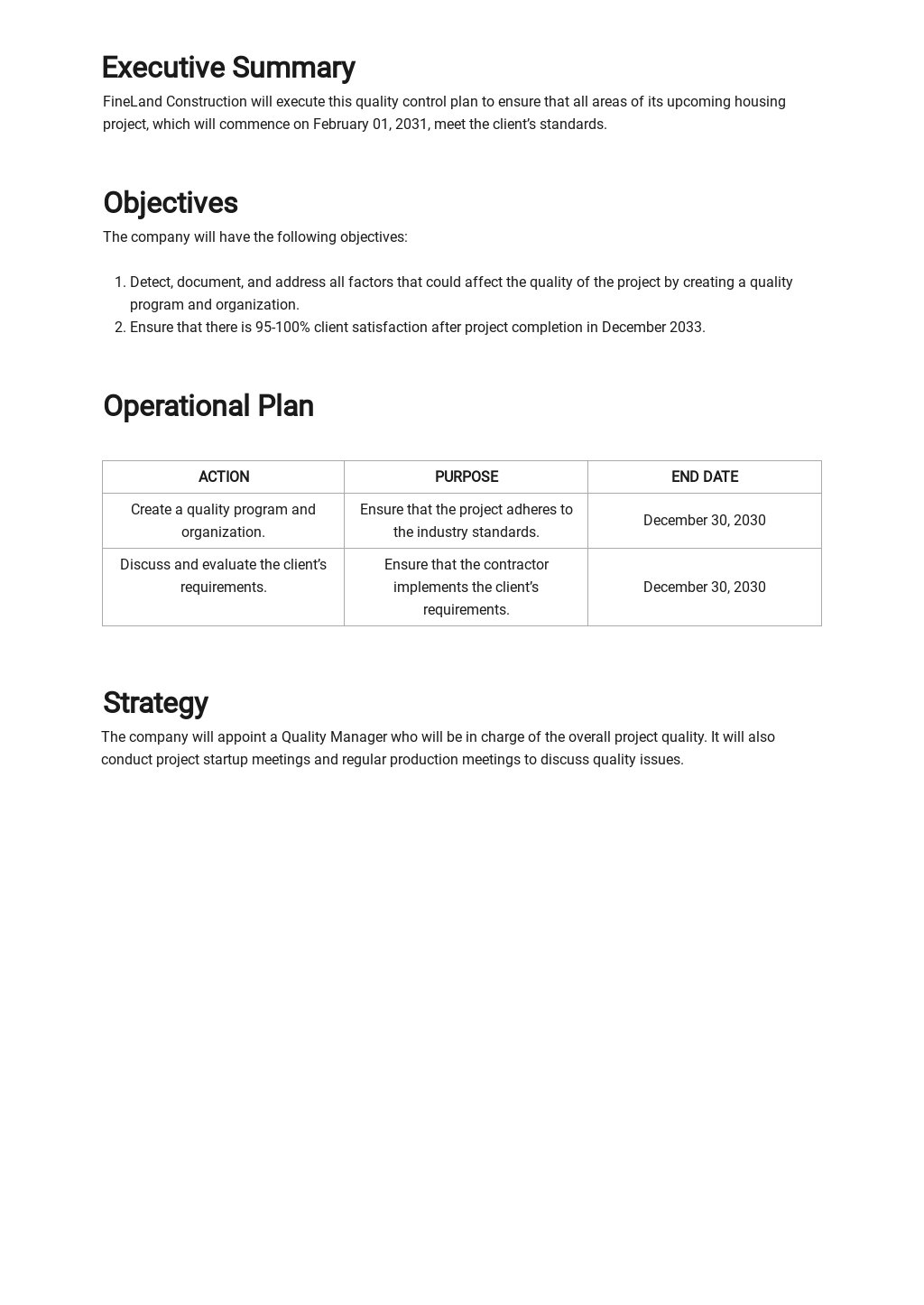

The Sealy mattress manufacturing process begins with extensive research and development to create innovative and comfortable designs. Once a design is finalized, the materials are carefully sourced to meet Sealy's high standards. These materials include a variety of foams, fabrics, and coils, each chosen for their specific benefits and functions. Next, the materials are carefully prepared and assembled by skilled technicians. The layers of foam and supportive coils are strategically placed in the mattress to provide optimal comfort and support for the sleeper. This process requires precision and attention to detail to ensure the mattress is consistent in quality and construction. Once the mattress is assembled, it goes through a rigorous quality control process. This involves thorough inspections and testing to ensure the mattress meets Sealy's standards for comfort, support, and durability. Any flaws or defects are addressed and corrected before the mattress moves on to the final step. The last step in the Sealy mattress manufacturing process is packaging and shipping. The mattress is carefully compressed, rolled, and packaged to make it easier to transport and set up in the customer's home. This also helps to reduce the company's carbon footprint and promote sustainability.Step-by-Step Guide to Sealy Mattress Production

Sealy has several factories located throughout the United States, each with state-of-the-art equipment and skilled technicians. The factories are designed to streamline the manufacturing process and ensure consistency and quality in every mattress produced. Inside the factory, you will find a variety of machines and tools used to cut, shape, and assemble the materials. These machines are carefully calibrated and maintained to ensure accuracy and precision in the production process. The technicians working on the mattresses are highly trained and skilled in their craft, and their attention to detail is essential in creating a high-quality product.Inside the Sealy Mattress Factory

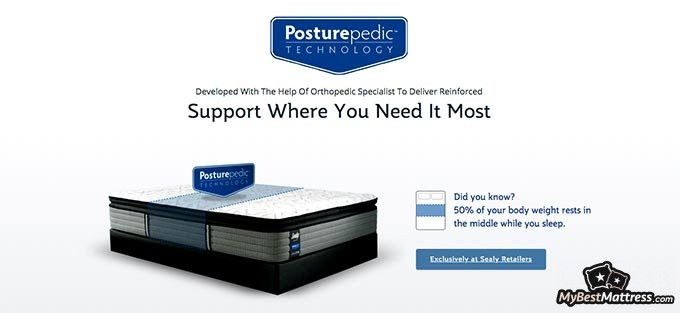

Sealy takes a scientific approach to mattress construction, using data and research to create the most comfortable and supportive mattresses possible. They have a team of experts dedicated to testing and improving their designs, incorporating advanced technologies and materials to enhance the sleep experience. One of the key elements of Sealy's mattress construction is their use of different types of foam. These foams are carefully chosen for their unique properties and benefits, such as pressure relief, temperature regulation, and support. By layering these foams in specific patterns, Sealy is able to create mattresses that cater to different sleep needs and preferences.The Science Behind Sealy Mattress Construction

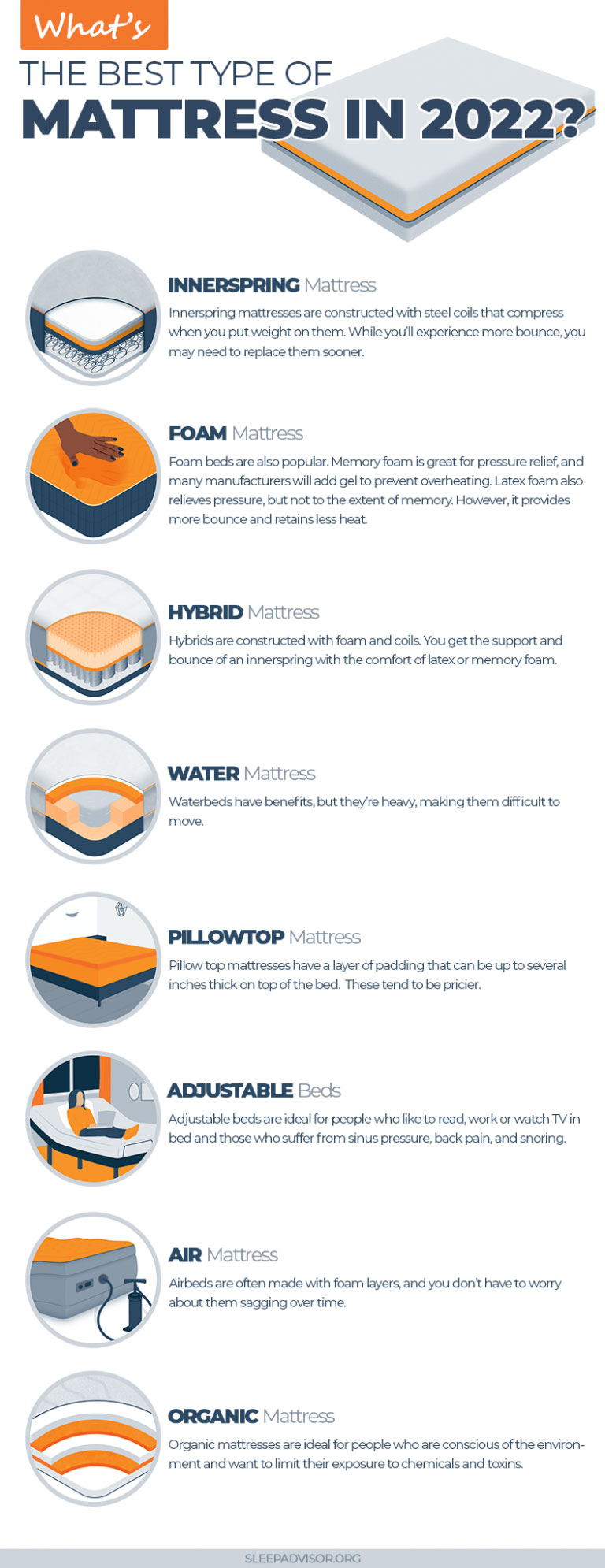

Sealy is committed to using high-quality materials in their mattresses, ensuring that each one provides the best possible sleep experience. Their mattresses may include memory foam, gel-infused foam, latex foam, and traditional innerspring coils, all of which offer different levels of support and comfort. In addition to the materials used inside the mattress, Sealy also pays attention to the materials used in the cover and other components. They source fabrics that are breathable, durable, and hypoallergenic, to create a well-rounded and comfortable sleep surface.Materials Used in Sealy Mattress Manufacturing

As mentioned earlier, Sealy has a strict quality control process in place to ensure their mattresses meet their high standards. This includes thorough inspections and testing, as well as a warranty to protect against any defects or issues that may arise. Sealy is confident in the quality of their mattresses, and they stand behind their products. This dedication to quality is a big reason why Sealy has been a trusted brand for over 130 years.Quality Control in Sealy Mattress Production

Sealy is always looking for ways to improve their mattresses and provide the best sleep experience for their customers. This has led to many innovations in their manufacturing process, such as the use of cooling technologies to regulate body temperature and the incorporation of advanced support systems for targeted pressure relief. Sealy is also committed to continuously researching and testing new materials and technologies to stay at the forefront of the mattress industry. This dedication to innovation ensures that customers can trust in the quality and comfort of Sealy mattresses.Innovations in Sealy Mattress Manufacturing

In addition to their commitment to quality, Sealy is also dedicated to promoting sustainability in their manufacturing process. This includes using eco-friendly materials and practices, as well as reducing waste and energy consumption. Sealy's efforts towards sustainability have earned them several certifications, including the CertiPUR-US® certification, which guarantees that their mattresses are made without harmful chemicals and substances. This commitment to sustainability not only benefits the environment but also provides peace of mind for customers.Sustainability in Sealy Mattress Production

As you can see, there is a lot that goes into the Sealy mattress manufacturing process. From extensive research and development to precise assembly, quality control, and packaging, every step is carefully executed to ensure a high-quality and comfortable mattress for customers. Next time you lay down on your Sealy mattress, you can appreciate the science and dedication that goes into creating the perfect sleep surface. And with Sealy constantly pushing the boundaries of innovation and sustainability, you can rest assured that you are getting the best possible sleep experience on a Sealy mattress.Behind the Scenes of Sealy Mattress Assembly

The Importance of Quality Materials in Sealy Mattress Manufacturing Process

Choosing the Right Material

When it comes to creating a comfortable and supportive mattress,

quality materials

are essential. That's why

Sealy

puts a great amount of effort and resources into sourcing the best materials for their mattresses.

Sealy

uses a combination of science and experience to determine which materials will provide the best sleep experience for their customers.

One of the key materials

Sealy

uses in their mattresses is

memory foam

. This material is known for its ability to contour to the body and relieve pressure points, providing a more comfortable and supportive sleep surface.

Sealy

also uses

gel-infused foam

in some of their mattresses, which helps regulate body temperature and keep sleepers cool throughout the night.

When it comes to creating a comfortable and supportive mattress,

quality materials

are essential. That's why

Sealy

puts a great amount of effort and resources into sourcing the best materials for their mattresses.

Sealy

uses a combination of science and experience to determine which materials will provide the best sleep experience for their customers.

One of the key materials

Sealy

uses in their mattresses is

memory foam

. This material is known for its ability to contour to the body and relieve pressure points, providing a more comfortable and supportive sleep surface.

Sealy

also uses

gel-infused foam

in some of their mattresses, which helps regulate body temperature and keep sleepers cool throughout the night.

Ensuring Durability and Longevity

In addition to comfort and support,

Sealy

also prioritizes durability and longevity in their mattress materials. That's why they use

high-density foam

in their mattresses, which is known for its resilience and ability to withstand years of use.

Sealy

also uses

individually wrapped coils

in their mattresses, which not only provide support but also help to minimize motion transfer for undisturbed sleep.

Furthermore,

Sealy

sources materials that are

hypoallergenic

and

eco-friendly

, ensuring that their mattresses are safe and sustainable for both the sleepers and the environment.

In addition to comfort and support,

Sealy

also prioritizes durability and longevity in their mattress materials. That's why they use

high-density foam

in their mattresses, which is known for its resilience and ability to withstand years of use.

Sealy

also uses

individually wrapped coils

in their mattresses, which not only provide support but also help to minimize motion transfer for undisturbed sleep.

Furthermore,

Sealy

sources materials that are

hypoallergenic

and

eco-friendly

, ensuring that their mattresses are safe and sustainable for both the sleepers and the environment.

The Manufacturing Process

Once

Sealy

has carefully chosen the materials for their mattresses, they go through a rigorous manufacturing process. This includes

handcrafting

each mattress and using state-of-the-art machinery to ensure precision and consistency. Each mattress is also thoroughly tested for quality and comfort before being packaged and shipped to customers.

In conclusion,

Sealy

understands the importance of using high-quality materials in their mattress manufacturing process. From choosing the right materials to ensuring durability and sustainability,

Sealy

is committed to providing their customers with the best sleep experience possible. When you choose a

Sealy

mattress, you can rest assured that you are investing in a product that is made with care and expertise.

Once

Sealy

has carefully chosen the materials for their mattresses, they go through a rigorous manufacturing process. This includes

handcrafting

each mattress and using state-of-the-art machinery to ensure precision and consistency. Each mattress is also thoroughly tested for quality and comfort before being packaged and shipped to customers.

In conclusion,

Sealy

understands the importance of using high-quality materials in their mattress manufacturing process. From choosing the right materials to ensuring durability and sustainability,

Sealy

is committed to providing their customers with the best sleep experience possible. When you choose a

Sealy

mattress, you can rest assured that you are investing in a product that is made with care and expertise.

:max_bytes(150000):strip_icc()/build-something-diy-vanity-594402125f9b58d58ae21158.jpg)