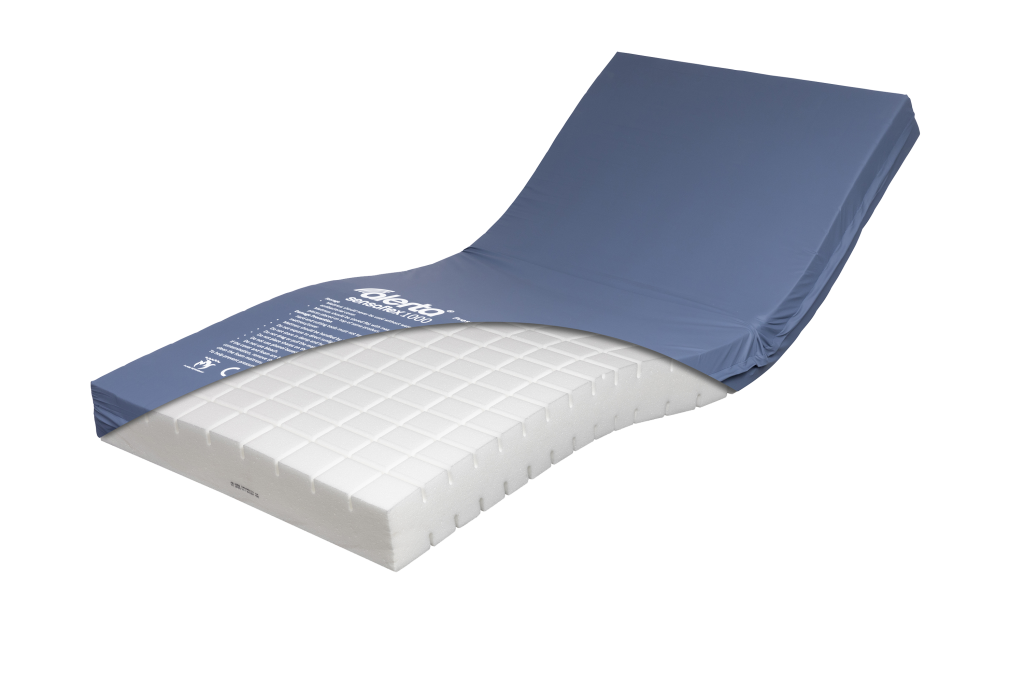

The foam mattress manufacturing process involves the creation of comfortable and supportive mattresses made from various types of foam materials. This process combines science, technology, and craftsmanship to produce high-quality mattresses that provide a good night's sleep for consumers. Let's take a closer look at the top 10 main profits in foam mattress manufacturing.Foam Mattress Manufacturing Process

There are numerous profits to be gained in foam mattress manufacturing. These include increased revenue, cost savings, improved efficiency, and more. Foam mattresses are becoming increasingly popular among consumers, and with the right manufacturing process, companies can reap the following benefits:Profits in Foam Mattress Manufacturing

One of the main profits in foam mattress manufacturing is the ability to produce mattresses at a lower cost. Foam materials are generally cheaper than traditional spring mattresses, making it cost-effective for manufacturers to produce foam mattresses in bulk. This allows companies to increase their profit margins while offering competitive prices to consumers.Foam Mattress Production Profits

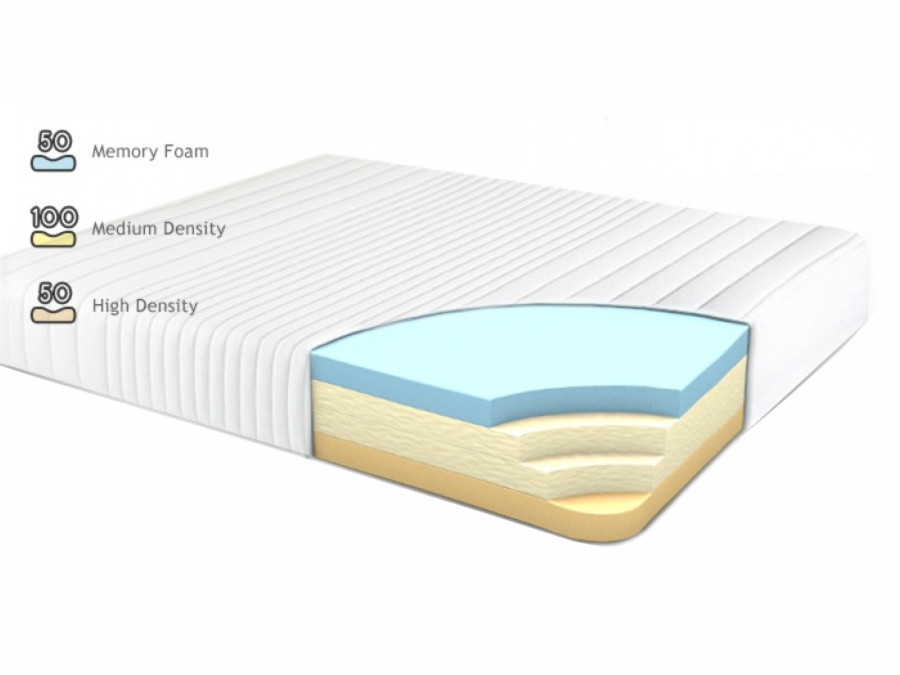

The profitability of foam mattress manufacturing is further increased by the variety of foam materials available. Manufacturers can choose from different types of foam, such as memory foam, latex foam, and polyurethane foam, to create mattresses with varying levels of comfort and support. This allows companies to cater to a wider range of consumer preferences and increase their market share.Foam Mattress Manufacturing Profitability

Another profit in foam mattress manufacturing is the reduced production costs. Foam materials are lightweight and easy to transport, which can result in lower shipping and handling costs. Additionally, the manufacturing process for foam mattresses is relatively simple and requires fewer resources compared to traditional mattresses, reducing overall production costs.Foam Mattress Production Costs

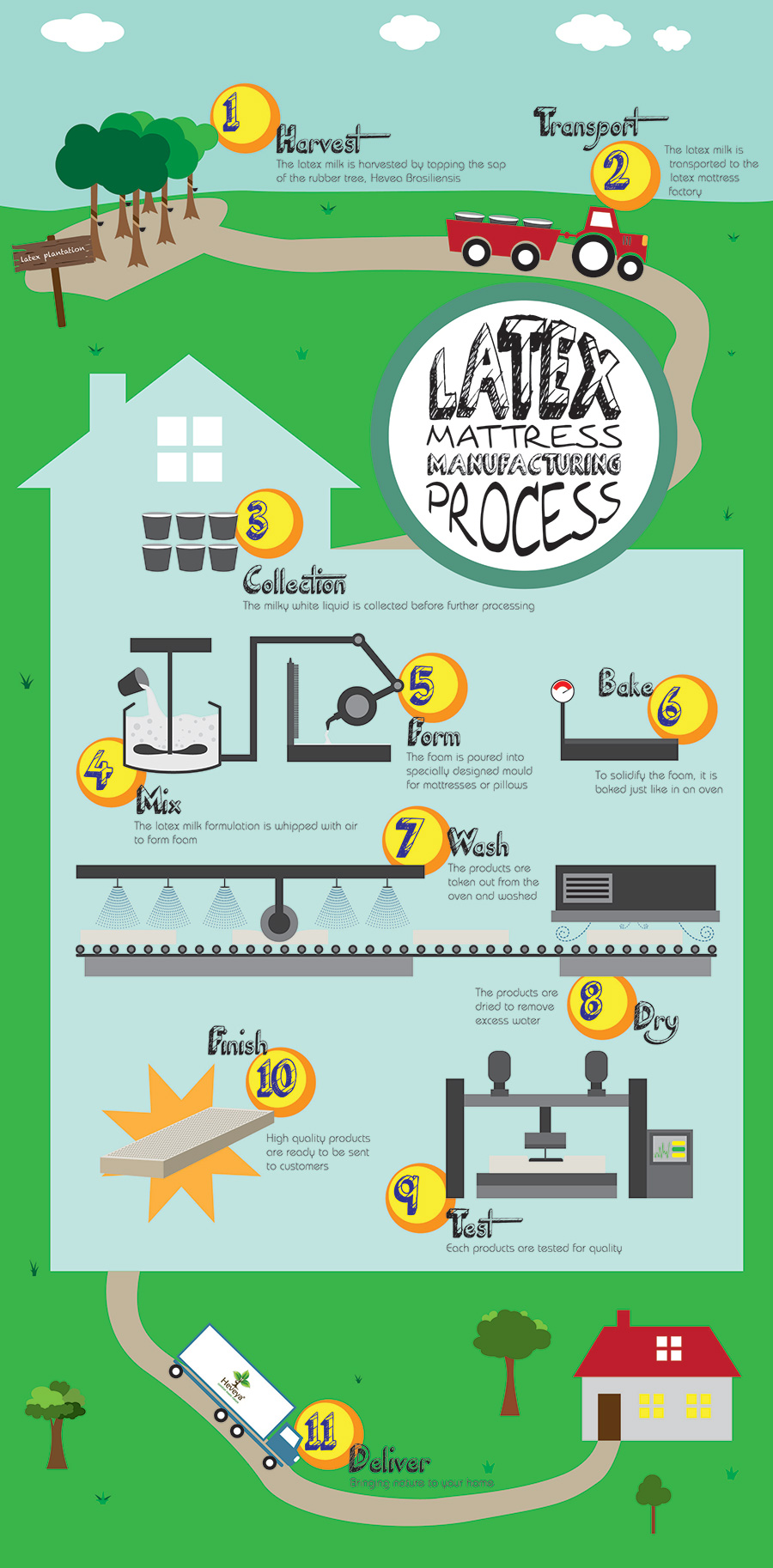

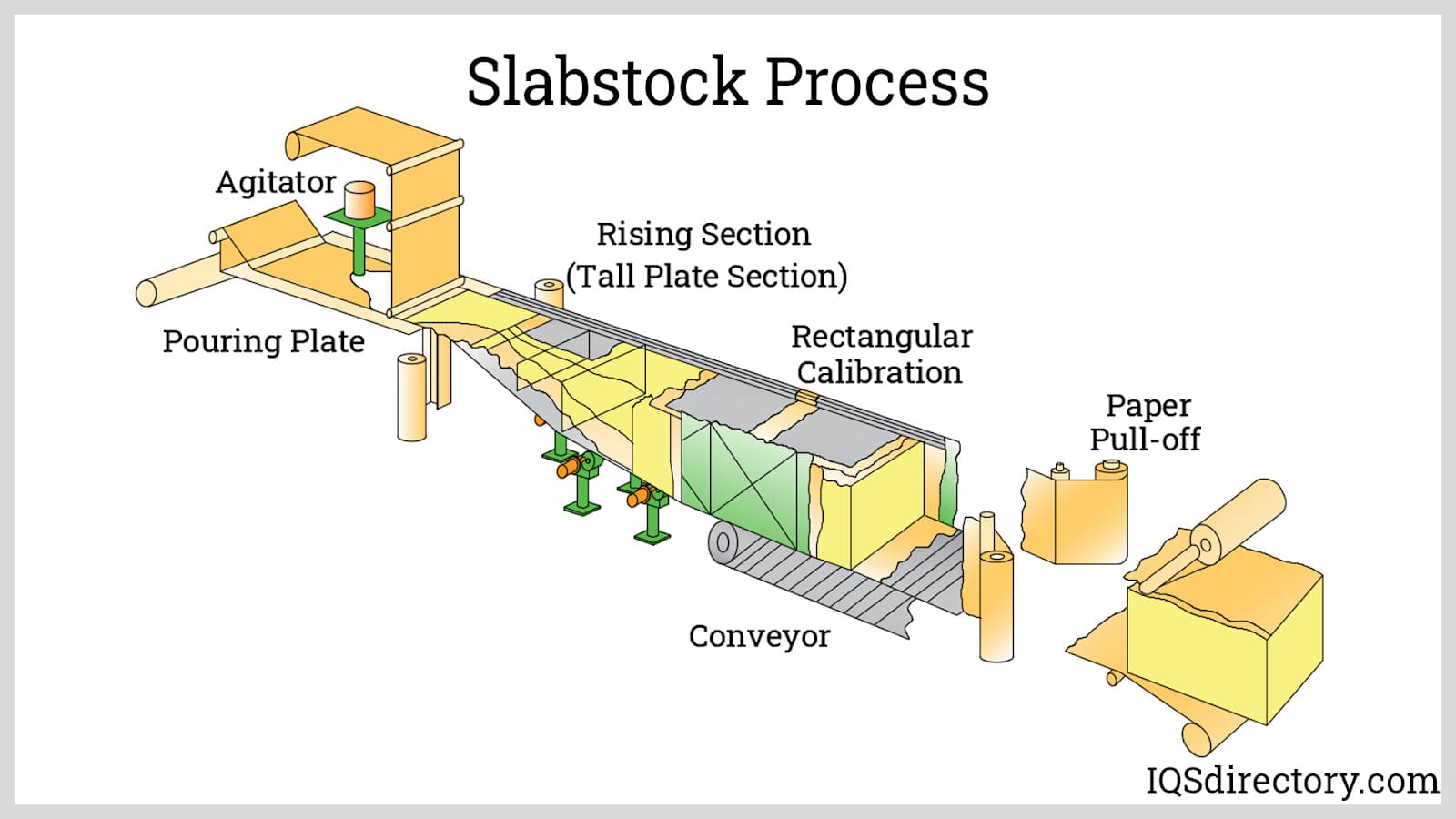

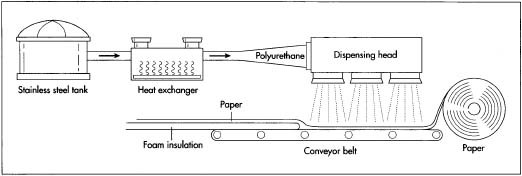

The efficiency of foam mattress manufacturing is also a significant profit. The production process for foam mattresses involves fewer steps, making it faster and more streamlined compared to traditional mattresses. This allows manufacturers to produce mattresses at a quicker pace, resulting in a higher output and increased revenue.Foam Mattress Manufacturing Efficiency

Optimizing the production process is another way to increase profits in foam mattress manufacturing. By utilizing technology and automation, manufacturers can improve the efficiency and accuracy of their production process. This can result in cost savings, reduced waste, and faster production times, ultimately increasing profits.Foam Mattress Production Optimization

The revenue potential for foam mattress manufacturing is significant. With the increasing demand for foam mattresses, manufacturers have the opportunity to generate higher revenue by offering a product that is in high demand. This can also lead to increased brand recognition and customer loyalty, further boosting revenue.Foam Mattress Manufacturing Revenue

The return on investment (ROI) for foam mattress manufacturing can be substantial. With the right production process and materials, manufacturers can produce high-quality foam mattresses that have a longer lifespan compared to traditional mattresses. This can result in repeat customers and increased sales, leading to a higher ROI over time.Foam Mattress Production ROI

Conducting a cost analysis is crucial for identifying potential profits in foam mattress manufacturing. By analyzing costs and identifying areas for improvement, manufacturers can make strategic decisions to increase profitability. This can include sourcing foam materials from different suppliers, optimizing production processes, and investing in technology and automation.Foam Mattress Manufacturing Cost Analysis

The Importance of Proper Foam Mattress Manufacturing for Ensuring Profits

Efficient Production Process

Foam mattresses have gained popularity in recent years due to their superior comfort and support. As a result, the demand for these mattresses has increased, making the foam mattress manufacturing process a highly competitive industry. In order to stay ahead of the competition and ensure profits, manufacturers must focus on creating an efficient production process. This involves using top-of-the-line equipment and technology, as well as implementing streamlined processes to maximize productivity and minimize waste. By investing in efficient manufacturing methods, companies can produce high-quality foam mattresses at a faster rate, leading to increased profits.

Foam mattresses have gained popularity in recent years due to their superior comfort and support. As a result, the demand for these mattresses has increased, making the foam mattress manufacturing process a highly competitive industry. In order to stay ahead of the competition and ensure profits, manufacturers must focus on creating an efficient production process. This involves using top-of-the-line equipment and technology, as well as implementing streamlined processes to maximize productivity and minimize waste. By investing in efficient manufacturing methods, companies can produce high-quality foam mattresses at a faster rate, leading to increased profits.

Quality Control Measures

In addition to having an efficient production process, it is crucial for foam mattress manufacturers to prioritize quality control measures. This involves conducting thorough inspections at every step of the manufacturing process to ensure that each mattress meets the highest standards. By maintaining strict quality control, companies can reduce the risk of producing defective mattresses, which can lead to costly returns and damage to their reputation. Furthermore, producing high-quality foam mattresses will result in satisfied customers, leading to repeat business and positive word-of-mouth referrals.

In addition to having an efficient production process, it is crucial for foam mattress manufacturers to prioritize quality control measures. This involves conducting thorough inspections at every step of the manufacturing process to ensure that each mattress meets the highest standards. By maintaining strict quality control, companies can reduce the risk of producing defective mattresses, which can lead to costly returns and damage to their reputation. Furthermore, producing high-quality foam mattresses will result in satisfied customers, leading to repeat business and positive word-of-mouth referrals.

Continuous Innovation

The foam mattress industry is constantly evolving, with new technologies and materials emerging all the time. In order to stay competitive and profitable, manufacturers must continuously innovate and adapt to these changes. This may involve researching and incorporating new materials, such as plant-based foams or cooling gel-infused foams, to meet the evolving needs and preferences of consumers. Companies that invest in research and development to improve their products will not only attract more customers, but also be able to charge a premium for their innovative and high-quality mattresses.

The foam mattress industry is constantly evolving, with new technologies and materials emerging all the time. In order to stay competitive and profitable, manufacturers must continuously innovate and adapt to these changes. This may involve researching and incorporating new materials, such as plant-based foams or cooling gel-infused foams, to meet the evolving needs and preferences of consumers. Companies that invest in research and development to improve their products will not only attract more customers, but also be able to charge a premium for their innovative and high-quality mattresses.

Conclusion

In conclusion, the foam mattress manufacturing process plays a crucial role in ensuring profits for companies in this industry. By focusing on efficiency, quality control, and continuous innovation, manufacturers can produce high-quality foam mattresses that meet the demands of consumers and stay ahead of the competition. With the increasing popularity of foam mattresses, it is essential for companies to prioritize their manufacturing process in order to thrive in this competitive market.

In conclusion, the foam mattress manufacturing process plays a crucial role in ensuring profits for companies in this industry. By focusing on efficiency, quality control, and continuous innovation, manufacturers can produce high-quality foam mattresses that meet the demands of consumers and stay ahead of the competition. With the increasing popularity of foam mattresses, it is essential for companies to prioritize their manufacturing process in order to thrive in this competitive market.

:max_bytes(150000):strip_icc()/bluebedrooms4-596ba2223df78c57f4a91f46.jpg)